Infineon Technologies AG and Schweizer Electronic AG have developed a new technology for the mild-hybridization of cars: chip embedding for Power MOSFETs. It will significantly improve the performance of 48 V systems while reducing their complexity. Continental Powertrain will be the first player to adopt the technology.

“Embedding Power MOSFETs will open a new chapter of possibilities for the electrification of mild hybrid cars,” said Dr. Rolf Merte, CEO at Schweizer Electronic. “The fact that one of the world’s leading automotive suppliers has chosen our technology confirms its potential.”

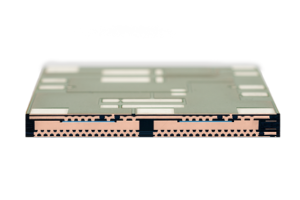

With chip embedding, the Power MOSFETs are no longer soldered onto a circuit board but integrated within. ”The resulting thermal benefits allow a higher power density and board integration enables further improvements in system reliability” said Dr. Frank Findeis, who is heading Infineon’s automotive MOSFET business. “These advantages result in higher power or more cost effective 48 V systems.”

As a first application, Continental Powertrain has decided to implement the new technology in a 48 V starter generator for vehicles from a major European carmaker.

“Chip embedding allows us to increase electrical power by 60 percent compared to a traditionally designed system,” said Dietmar Vogt, System Technical Project Leader at Continental Powertrain.

48 V starter generators are a key contributor to the CO2 reduction of up to about 15 percent achieved by a mild hybrid vehicle compared to a conventional drive train. They allow the engine to be stopped more often and for a longer duration than a 12 V based start-stop-system. Furthermore they can boost acceleration and thus reduce load on the combustion engine. During braking they recover more of the kinetic energy than a 12 V system.

Infineon contributes its leading MOSFET technology OptiMOS™5 to the new approach, Schweizer its embedding power PCB technology called Smart p² Pack®. The partners plan to start mass production in 2021.