Exoskeleton is defined as supporting or a protective covering. It is placed on the user’s body and reinforces or restores human performance. It should not be mistaken with the mechanical prosthetic as they replace the original body part rather than augmenting it. It can also be defined as the application of robotics and biomechatronics towards the augmentation of humans in the performance of a variety of tasks.

Comau unveils MATE, its first innovative wearable exoskeleton, for the first time in North America, at Automate 2019, the broadest automation solutions event in North America. MATE has been designed to improve work quality in an efficient and highly ergonomic manner by providing consistent and advanced movement assistance during prolonged overhead, as well as daily tasks.

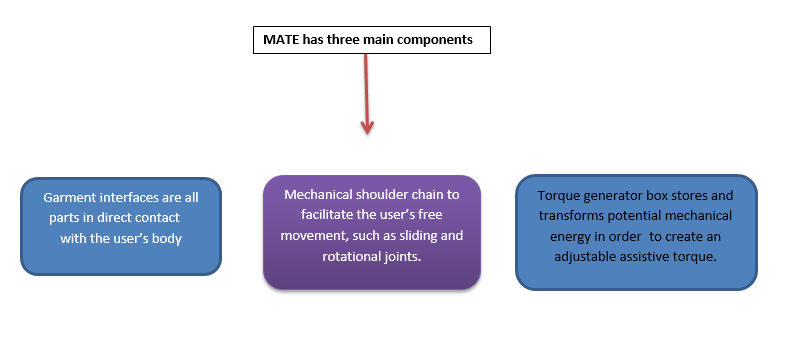

The MATE Fit for Workers exoskeleton used an advanced passive structure. MATE delivers lightweight, breathable and highly effective postural support without the need for batteries, motors or other devices.

It is also compact and ergonomically designed thanks to the partnership between Comau, ÖSSUR, a leading non-invasive orthopaedics company, and IUVO, a spin-off company of the BioRobotics Institute (Scuola Superiore Sant’Anna) specialized in wearable technologies. MATE is fully able to replicate any movement of the shoulder while adhering to the body like a “second skin”.

MATE technology aims to reduce fatigue and improve the quality of work by reproducing and enhancing the physiological movements of the upper limbs. MATE originally was designed for vehicular underbody tasks during the finishing phase of assembly. However, it also can be effective for any task that requires the use of the upper limbs, specifically for those that require a flexion-extension of the shoulder. Other applications are drilling, assembly of electrical appliances, and boxing and unboxing.

The MATE exoskeleton reproduces the biomechanical structure of the shoulder. It alleviates the arms’ weight by ergonomically redistributing it to the back. The springs store the potential energy of the flexion and extension motion of the arm, and then reproduces the physiological movement of the shoulder. It is a totally passive exoskeleton technology based on a system of springs, leverage, and the shoulder kinematic chain, with no need for a battery and actuators.

How MATE works

Features:

- Designed in close collaboration with factory workers engaged in manual activities

- Naturally comfortable, breathable postural structure

- Compact structure fully follows the movements of the upper limbs without resistance or misalignment

- Passive mechanism – no need for battery, motors or other devices

Benefits:

- Reduction of shoulder muscle activity

- Users can do the same tasks with less fatigue

- Consistent, ergonomically-assisted movement support increases the quality and precision of overhead tasks

- Users can improve the quality of their work