A team of students from Munich University of Applied Sciences has successfully applied for the “Fly Your Thesis 2020!” campaign of the European Space Agency ESA. At the beginning of November 2020, experiments in zero gravity will be carried out in Bordeaux as part of its 3D printing campaign. The eight members of the AIMIS-FYT team are aerospace engineering students at Munich University of Applied Sciences. The name AIMIS stands for Additive Manufacturing in Space. Their project aims to demonstrate a 3D printing process that can be used to produce structures for solar panels, antennas, or other installations in space.

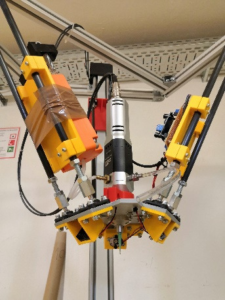

Printing is being tested with a 3D print head from ViscoTec: the vipro-HEAD 5, a one-component print head that has already proven itself in numerous applications with viscous materials and pastes. The materials are conveyed purely volumetrically. The endless piston principle guarantees precise printing results: during transitions to a new line, unwanted threads can be avoided thanks to a programmable suck-back. Process fluctuations such as viscosity, pressure and temperature are also levelled out within the printing process.

The AIMIS-FYT team use a UV resin for the experiment. The resin is extruded and cured by UV light. The experiments of the three parabolic flights will be carried out in November. 30 parabolas are planned per flight, on which zero gravity is maintained for 20 seconds from one turning point via the peak to the other turning point of the parabola. During this time the experiments can be carried out. The AIMIS-FYT team has the possibility to implement a total of eight experiments to study the 3D printing process under conditions of microgravity. Straight bars, bar connectors or free-form bars will be generated. For the first six modes, a conventional printing plate is used as the starting point for printing. In the last two experiments, the behavior of pressing, free-floating bars will be observed. The main parameters of the printing process will be the extrusion speed of the resin, the UV light intensity, the UV light time, and the trajectory of the printer. The number of parabolas allows each experiment to be repeated several times with different parameter settings.

At present it is only possible to transport equipment or spare parts into space at great expense. In an interview, Torben Schaefer, press spokesman for the AIMIS-FYT team, explains more about this exciting project:

Click here to read the full interview