Advantages of the endless piston principle for trickling

Resin impregnation of rotor and stator – an important process in the production of electric motors. Especially with the electrification of the powertrain in the automotive sector, the demand for durable engines with maximum power density and low noise emissions is increasing. This white paper deals with automation solutions, especially for impregnating electric motors and the advantages of the various resin impregnation methods. Trickling in particular – with the right dispensing technology – offers great potential with regard to the optimization of individual production steps.

Insulation and trickle impregnation of stator and rotor windings

The quality of the insulation in electric drives determines, among other things, the durability and efficiency of the motor. The round or flat wire required for the coil is first coated with a layer of varnish (primary insulation) to ensure electrical insulation. Then a sliding layer is applied to the round wire to facilitate winding.

After winding the round wire or after joining the flat wire, resin impregnation is applied: a resin is applied to the wire to fill cavities within the windings or between the winding and the laminated cores. And to displace air bubbles. It is important that the resin system has a low viscosity and is dispensed continuously without any air bubbles. Only in this way can it creep optimally into all cavities. The temperature during the preheating, trickling and curing process is also a process-determining variable that – in conjunction with the component – must be defined for the respective material. The so-called secondary insulation increases the resistance of electrical rotating machines (electric motors and generators). This is because vibrations are minimized by closing and sealing the cavities. These could lead to short circuits and cause noise. The mechanical resistance is therefore strengthened.

As already mentioned, the resin impregnation also serves the purpose of displacing air bubbles. Air is a good heat insulator and would impede the desired heat dissipation. If these air bubbles are filled by an impregnating resin, a complete thermal coupling between the sheet metal package and the windings is established. The heat can be optimally dissipated. In high-voltage applications, air can also cause an electrical breakdown. Thanks to the encapsulation, the electrical insulation within the windings is additionally improved and short circuits caused by damage to the copper enamel can be prevented. The resin also provides protection against chemical attack, moisture and dust. Overall, resin impregnation can result in longer life and improved performance.

Frequently used resin impregnation processes

- Dipping: the preheated component is immersed into the resin pool at a defined speed. The impregnating resin can already gel due to the heating of the winding during the dipping process. This in turn reduces dripping losses. In the so-called roll dipping process, the component additionally rotates during and after the dipping process. The component is then cured in a heating section.

Advantages of dipping:

- Every construction size is adaptable

- Low investment costs without rotation

- Easily scalable for high volumes

- Vacuum potting: the stator is clamped in a mould into which the liquid resin flows and slowly rises to the top. A sealing core is placed in the centre of the stator to ensure vacuum tightness. The entire space or component is evacuated. The evacuated resin impregnation material is introduced under vacuum. Air bubbles and cavities are reliably potted and copper windings, undercuts and gaps are completely filled with the potting compound. After the material has cured, the sealing core is removed again.

Advantages of vacuum potting:

- Cavities are avoided

- High quality of resin impregnation

- The possibility of using two-component materials

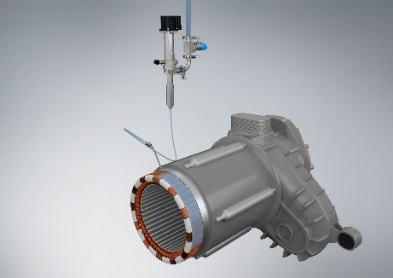

- Trickling: in trickling, the stator is clamped on a mandrel and continuously rotated around its own axis in horizontal alignment. The component is heated by conventional furnace heating or induction. During rotation, the low-viscosity resin is trickled through several nozzles at different positions by means of a metering system. By capillary action, the resin penetrates the windings – and is distributed evenly in the stator. For a high-quality resin impregnation result. The trickle process is particularly suitable if only certain areas of the component are to be wetted with a resin.

Advantages of trickling:

- The dispensing quantity and dispensing flow are adjustable with precision -> low resin consumption at high filling level is possible

- Optimal for the application of two-component resin impregnating materials -> fast curing at low temperatures is possible -> reduction in investment and operating costs

- Clean process through defined material consumption -> no contamination of the plant with resin impregnation material

Trickle materials

Frequently used as resin impregnating materials are one and two-component, cold or hot curing epoxy resin systems and polyester resins. These materials have low viscosity so that they can be poured into any cavity, even narrow areas of the windings. Most resins are thermal curing. Typical properties of impregnating resins are good electrical insulation and high crawl ability.

One-component resins have the advantage that the process is particularly robust, and no mixing is required. They are excellently suited for trickling and dipping processes. The investment for a dispensing system to convey a one-component material is significantly lower than for a two-component material. Curing is achieved by the use of thermal energy and may require long heating facilities.

Two-component resins combine several advantages: they have a short curing time, which in turn requires a shorter heating section and ultimately means lower investments and, above all, lower energy costs in production. They also have a precisely defined curing time and better storage stability. After curing, the resin becomes a hard-elastic moulding material. The disadvantage is a more complex process – due to the dispensing parameters required for different mixing ratios and the selection of a suitable static mixer.

Advantages of the endless piston principle for trickling

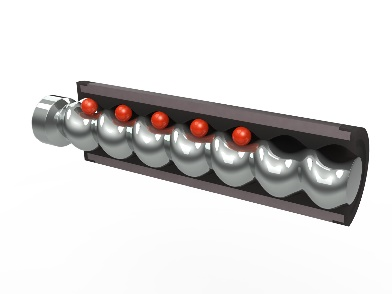

When impregnating electric motors by trickling, the progressive cavity technology, on which ViscoTec dispensing systems, for example, are based, ensures the best results. The operating principle is based on the endless piston principle. A stainless-steel rotor performs an eccentric rotational movement in the elastomer stator. The resulting feed cavities within the progressive cavity pump form a defined volume: an exact quantity is dispensed per revolution. Due to the proportionality between drive speed and discharge volume, the dispensing volume as well as the dispensing speed can be easily regulated. Should the process parameters change due to a change of component or material, both the dispensing volume and the dispensing speed can be adjusted easily and quickly via the ViscoTec control system.

The trickling of two components requires precise adjustment and calibration of both dispensers and the correct selection of a static mixer. ViscoTec’s two-component dispensing systems are modular and can be combined in different sizes to achieve even extreme mixing ratios. Both components are conveyed completely separately until they enter the static mixer. This prevents curing within the dispensing equipment. The correct selection of the static mixer is decisive for good mixing. ViscoTec, for example, offers a wide selection of suitable connection systems. The connection of all common mixers is therefore possible at any time.

Progressive cavity pumps operate with low shear, without valve and pulsation-free. Uniform, pulsation-free dispensing is an important prerequisite for high-quality trickling results: the sealing line between the rotor and stator produces minimal shear on the dispensing material and at the same time provides a sealing reserve without a valve. Different viscosities, thixotropic properties, high solids content and reactive dispensing materials require very gentle handling. The endless piston technology is pressure stable and independent of viscosity. It achieves a particularly high dispensing accuracy. The guaranteed repeatability of >99 % is exceeded by ViscoTec in most applications. The programmable suck-back feature prevents material from being thrown away by dripping from the dispensing nozzles.

In addition to the dispensing, the removal and, if necessary, the treatment of the materials to be dispensed must also be considered. Since the result of the resin impregnation must be free of bubbles, it is recommended to treat the material with a treatment system, such as degassing, before the dispensing process. However, the chemical and rheological properties must remain unchanged. Sedimentation cannot be excluded with filler-loaded resins; however, it can be prevented by a suitable stirrer or a circulation process.

ViscoTec covers the complete portfolio – from removal and material treatment to precise application of the materials to be dispensed. You can find more information on the website at https://www.viscotec.de/en/products/