Dispensing solutions for a wide range of applications

Sensors are potted in order to permanently protect electronic components from external influences such as heat, moisture, vibration, or chemical influences. ViscoTec dispensing pumps ensure high-precision, high-quality potting processes in the most diverse applications. In combination with the appropriate one or two-component potting materials for the respective application, perfect, customer-specific solutions are created. Depending on the application, the dispensing pumps master a variety of challenges.

Example from optoelectronics: Fork photoelectric sensor

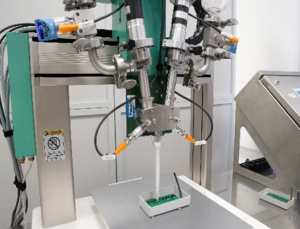

A potting application, using the 2-component dispenser ViscoDuo-VM, has been designed in a joint project with Fichter Maschinen GmbH. Due to a flexible human-robot collaboration, dispensing can be carried out manually as well as automatically. In this application, special attention is paid to maintaining the homogeneity of the material “Component A”. This is achieved by recirculation of the material and a specially designed agitator in the ViscoTreat-R storage tank. In addition, the use of a silica gel filter prevents the material from becoming exposed to moisture.

The system is completely flexible: Thanks to the integration of a palletizer for the product carriers, a fully automatic production process is possible. This will enable long, self-sufficient running times of the system without the need for operating personnel. At the same time, the system concept also offers the possibility to pot individual product carriers or even just individual sample parts manually via the manual workstation function.

With the endless piston technology built into the ViscoTec dispensers, large quantities can also be dispensed continuously. At the same time, even very small quantities or dots can be precisely dispensed with one and the same system. The flow rate can be adjusted at any time by analogue control of the dispensing drives via the main PLC.

A particular challenge in the implementation of the project was the precise maintenance of the fill level on the components of the fork photoelectric sensors. The issue was solved by implementing a two-stage potting process. During the first stage, the so-called pre-sealing, the material is dispensed at a higher dispensing speed, up to a fill level of approx. two thirds. As the complete product carrier is processed, there is sufficient time for the dispensed material to distribute itself cleanly in the component to ensure that all plates, wires, and connections are covered. In the second stage, the so-called deck potting, the height of the component is established. The remainder of the potting process follows until the sensor detects the potting height required. A triangulation laser sensor detects the height of the component and the fill level. When the optimum fill level is reached, the dispensing stops. Thanks to the programmable suck-back of the potting material at the end of the process, the dispensing unit is removed cleanly without risking contamination of the component by dripping. This second potting step is implemented with a reduced dosing speed.

Example from electrical engineering: temperature sensors

With a 1K RD Dispenser from ViscoTec, a temperature sensor is embedded in the sensor tube with thermal paste. It is important that no air bubbles remain in the sensor tube during dosing, which would falsify the temperature measurement. In this case, the material is available in the delivery container free of air bubbles (this variant is often offered by the material manufacturers at an additional cost). Alternatively, a processing system can be integrated.

With this application there are again two possibilities for implementation:

- Manually: The sensor tube is pushed onto the dispensing needle by hand and, after the start of the potting process (quantity dosing, via programmable servo motors or separate HMI), is pushed back down from the dispensing needle by the resulting material pressure as the fill level rises. With longer sensors, it may be necessary to guide the sensor tube. At the end of the dosing, the operator takes the filled probe out of the device.

- Automated, in combination with a system or machine builder: The dispenser is permanently installed and the sensor tube is automatically pushed over the dispensing needle by a robot. Dosing is started and ended by the higher-level controller. The mechanics coordinate the travel and dosing speed. The dosing amount results from the running time of the dispenser (dosing time) and the dosing speed. The speed can be flexibly changed and adapted during the dosing process (0 to 10 V / 4 to 20 mA or via bus).

Example 1 from the automotive sector: engine ignition for internal combustion engines

Sensors for the ignition of diesel engines are encapsulated in an immersion bath – a package with ten pieces each is immersed in 3K material. The immersion bath must be kept at a certain level in order to ensure a uniform potting result for the individual sensors. A 2K epoxy resin is used, to which a water repellent is added as the third component. Water repellants prevent the ingress of moisture, which would destroy the sensor. The mixing ratio of the three components is 100: 5: 15 (A: B: C).

Component A is degassed with a ViscoTreat-Im processing system and conveyed from there. For the two low-viscosity components B (hardener, catalyst) and C (water repellent), plastic storage containers made of PE with a capacity of 180 ml are provided. These are mounted directly on the respective dispenser. In the first step, components A and C are mixed in a mixing ratio of 100: 15 with a 2K dispenser ViscoDuo-P 4/3 and fed to a further 2K dispenser ViscoDuo-P 3/3. In this component B is added in a mixing ratio of 100: 5. The ready-mixed, three-component material is fed to a 1K 3RD4 dispenser, which is used to dose the defined amount. At peak times, two dispensers can be operated in parallel to shorten cycle times.

Example 2 from the automotive sector: headlight potting

In this application example, headlights are cast with a 2K silicone in a mixing ratio of 10: 1. The quantities to be dosed vary between 20 and 80 ml. The 2K dosing system from ViscoTec used for this purpose consists of a stationary and a mobile part. The stationary part contains the two ViscoTreat-R 3/22 used for supply as well as the overall control of the system. A 2K dispenser ViscoDuo-VM 12/8 forms the second mobile part.

After the successful implementation of the system, a central supply for six 2K dispensers with different discharge capacities was introduced later. The supply takes place as follows: Component A is made available in a 200 l drum with agitator. A 3VMP36 extraction pump, which is located next to the container, uses a vacuum to suck the material out of the drum into an 80 l storage container. Component B comes from a 30 l metal canister and is also sucked into a ViscoTreat-R 3/22 using a vacuum. Both materials circulate in an approx. 65 m long ring line. In the course of the ring main there are six outlets with ball valves to which the 2K dispenser are connected.

Dosing tests: no two potting sensors are the same

Which influences the individual sensors are exposed to, or which the potting compound has to withstand, depends very specifically on the respective application. The dosing solutions developed for this vary just as widely. Only a carefully selected dosing technology and the right material ensure the specified, reliable results, a safe process and thus high-quality sensors. For this, a close cooperation between the material manufacturer, the dosing specialist and usually also the machine and system builder is essential.

Extensive dosing tests are used to determine which material best withstands the requirements and which dosing processes ensure the required characteristics. Of course, important results of the dosing tests are also costs or economical processes and realistic cycle times.

For detail information visit: https://www.viscotec.de/en/sensor-potting/