LCD (Liquid Crystal Display) is the only display technology that response time is a concern. Other display technology like OLED (Organic Light Emitting Diodes) , CRT(Cathode-Ray Tube), Plasma, VFD(Vacuum Fluorescent Display) and most recent Samsung MicroLED displays don’t have the response time issue.

The reason why LCD displays have slower response times is because the liquid crystal material is organic material fluid sandwiched between electrodes of two pieces of glass substrates. The liquid crystal molecules are twisted parallelly between the electrodes when power is applied, the liquid crystal molecules are forced into a perpendicular position to the electrodes. This process takes time, hence response time, because the liquid crystal fluid has viscosity. The higher viscosity, the longer response time. That explains why the colder the temperature, the slower the LCD responds. If you read a LCD display datasheet, you will find the LCD display has storage and operating temperature range. The LCD display should have reasonable response speed depending on the applications.

Normal monitors have 10ms (millisecond) response time. If you try to buy a monitor for gaming or a TV to watch sport, the required response time should be pretty fast (around 1ms). The extreme example is the LCD welding helmet, it requires very fast response time (<0.1ms) to prevent the welder’s eyes hurt by UV. But some applications require slower response time for LCD display, for example, an avalanche transceiver has very low refresh rate in order to save power, it requires LCD very slow response time in order to avoid flickering. In the following, we will mainly try to increase the LCD response time as the target.

What Is Response Time?

Response time of an LCD screen is the time it takes to shift from one color to another. Normally, it is measured to change from black to white back again to black . But more accurately, it should be gray to gray because the LCD display shows grayscale and then color shade (gradations) most of the time instead of purely black and while or RGB (Red Green Blue) colors.

How to Increase LCD Response Speed (Decrease Response time)?

Normally, there are two directions to increase LCD response speed: The LCD cell and LCD driving improvement

1, LCD cell manufacturing and technologies

- Use lower viscosity liquid crystal materials

As we know that high viscosity is the main reason to slow down LCD twisting. Chemists invent ways to reduce the viscosity. There are many patents on this topic.

- Reduce the LCD cell gap

Normally, the liquid crystal material is sandwiched between two electrodes with a gap around 6 to 7 um(micrometer) which gives the LCD around 25ms at room temperature. The response time is not good enough for TV. With the reduction of the cell gap, the electric field is bigger which applies more power to force liquid crystal modules to make the change. But decreasing the gap has the negative impact of lowering production yield which will drive the LCD screen price up.

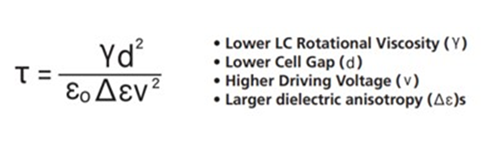

There is a formula to calculate the relationship of response time to viscosity and LCD cell gap as below. From here, we can see that cell gap can affect the response speed the most.

- LCD technologies

Although all the LCD displays include liquid crystal materials and need to fight with viscosity. The structure inside of the cell can be different. Considering the most popular LCD types, TN (Twist Nematic) LCDs are faster than STN (SuperTwist Nematic) LCDs; Active Matrix (with TFT: Thin Film Transistor) LCDs are faster than Passive Matrix LCDs, IPS (In-Plane Switching) LCDs are faster than TN type LCDs.

2, LCD Driving Technologies

- Overdrive Circuits

It is the same principle as to reduce the LCD cell gap. The purpose is to use higher voltage to increase the electric field and to force liquid crystal molecules to turn faster. By using an overdrive circuit the middle gradation response time is to approach the black-white-black one regardless of which system drives the LCD panel.

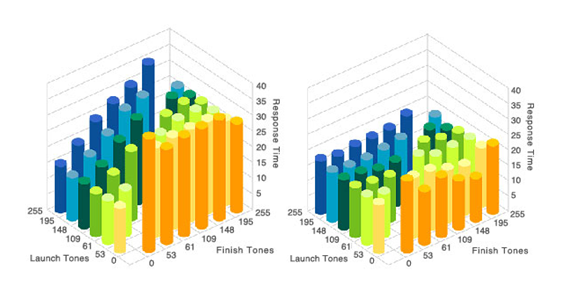

Fig.2 This graph compares the response time with and without an overdrive circuit (0 = black, 255 = white). Without an overdrive circuit the middle gradation response times are slow and vary widely according to the tone (photo on the left). With an overdrive circuit the response times become uniform over the entire range of tones (photo on the right).

But there are also drawbacks to use the overdrive circuit as it will change the color balance to make it drift away from the original video source. This is because applying extra voltage to the liquid crystal cell can make it overleap the target tone. For example, when changing from gray tone “50” to “100”, a tone higher than “100” is instantaneously displayed on the screen. This is called overshoot / undershoot.

- Black Frame Insertion (BFI)

It is a technique to reduce blur and afterimages. Normally the refresh rate of an LCD is 60 Hz. This means that the screen (frame) changes 60 times in a second. Inserting a pitch-black screen between the frames reduces the appearance of blur and afterimages. This technique is widely adopted for household LCD TV and is very effective. But the drawbacks of black insertion are that it reduces brightness and causes flickering. In order to overcome the issue, some LCD panels increase the refresh rate to 120 Hz.

Fig.3 Normal LCD (60Hz) vs Black Frame Insertion and 120Hz

- Accelerator Driver

It is similar technology as Black Frame Insertion. But instead of insert a black frame in the display, the technique shuts down the CCFL backlight tubes one at a time, in sequence, the screens were artificially helping to clean the retained image from the eye.