As the global population experiences rapid growth, more people around the world are moving from the countryside to the city. In addition to the inner-city challenges posed by the urbanization megatrend, there is also an increase in the average traveling distance. As a result, the challenges for train systems are also increasing. To meet these demands, Siemens Mobility and Infineon Technologies AG have jointly developed new auxiliary converters to improve the efficiency of on-board power systems using power semiconductors based on silicon carbide (SiC).

“Our vehicles should not only offer the highest level of passenger comfort but also enable our customers to operate them sustainably over the entire product life cycle. Energy-efficient on-board train power systems can make a major contribution to economical and environmentally-friendly train operations,” said Albrecht Neumann, CEO of Rolling Stock at Siemens Mobility.

Siemens Mobility uses the new converter for various train platforms. As a result, the platforms are maintenance-friendly, reliable, economical and, above all, power efficient. “With SiC, we achieve higher switching speed as well as efficiency to reduce the size of transformers, capacitors, cooling elements and the housing unit. The advantages of this semiconductor material are evident and are now being leveraged in rail-bound vehicles,” said Dr. Peter Wawer, President of Infineon’s Industrial Power Control Division.

In addition to providing the AC voltage (e.g., 3 AC 400 V 50 Hz) required for the vehicle power system, auxiliary converters also deliver the required battery voltage (e.g., 110 V DC). To achieve this, they convert the DC voltage provided at the converter input. They ensure that train passengers can charge laptops and smartphones; the air conditioning and ventilation systems are running; and the on-board restaurant can offer hot and cold drinks and food. Without them, connectivity, information or entertainment services on trains would not be available. As part of the system, SiC reduces the overall costs in the on-board electrical system and the energy consumption of the auxiliary converter. It also enables more compact and lighter converter designs, along with a modular and service-friendly design to ensure lower maintenance costs.

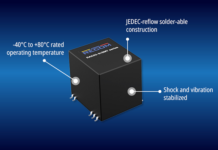

The auxiliary converter makes use of power semiconductors in a half-bridge topology that are based on Infineon’s CoolSiC MOSFET 1200 V technology. Depending on the design, 8 to 16 half-bridge modules are installed for each converter.