Reducing power consumption and design load in compact industrial equipment and home appliances

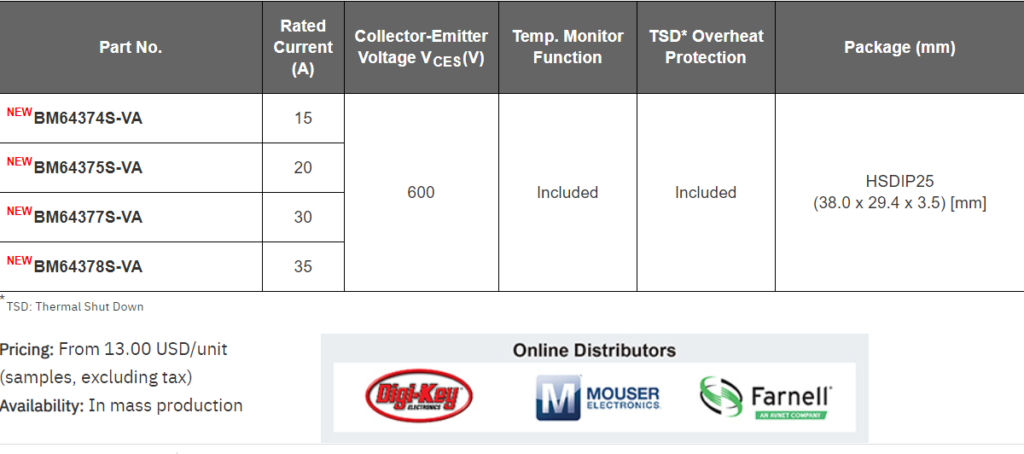

ROHM developed four new 600V IGBT Intelligent Power Modules (IPMs), BM6437x series, that deliver best-in-class low noise characteristics together with low loss ideal for power conversion in inverters. The devices are used in compact industrial equipment, such as small capacity motors for robots, as well as home appliances – including air conditioners and washing machines.

In recent years, with the proliferation of IoT and increasing power consumption following the automation of industrial equipment and home appliances, there is a need for lower power consumption when considering power utilization and limited global resources. This requires higher efficiency IGBTs – one of semiconductors responsible for power conversion – along with modules equipped with them to further reduce power consumption.

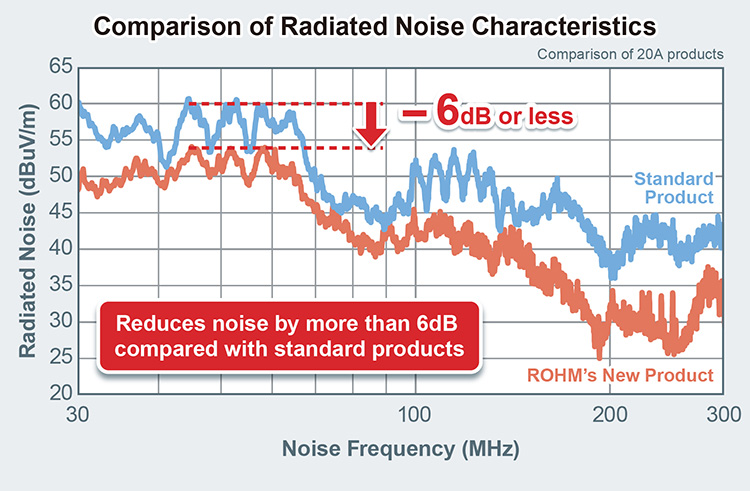

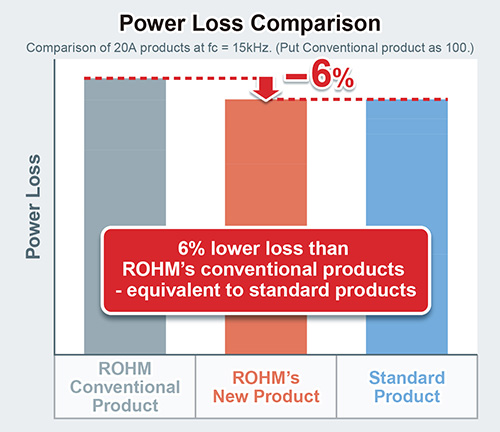

However, in general, when developing IGBT IPMs, the noise characteristics often deteriorate as priority is placed on low loss to reduce power consumption, making it necessary to improve noise performance. In response, ROHM developed a new 4-model lineup of IGBT IPMs that achieve class-leading characteristics by simultaneously reducing both radiated noise and power loss. Optimizing the built-in IGBT’s characteristics and soft recovery characteristics of the internal FRD (Fast Recovery Diode) allows the BM6437x series to decrease radiated noise by more than 6dB (at peak comparison) over standard products, making it possible to consider simplifying the noise filter that is typically required. Also, the latest low-loss IGBTs adopted in these IPMs reduce power consumption over ROHM’s conventional IPM products by 6% (fc=15kHz), achieve class-leading low loss, and contribute to reduction of various equipment power consumption. In addition, the new product dramatically improved the built-in temperature monitoring function, results in high ±2% accuracy (equivalent to 2°C). This makes it possible to consider eliminating the external thermistor required with existing high accuracy temperature monitors, reducing the number of external parts along with design load. Furthermore, a new function for identifying the product after mounting has been added to help prevent mounting errors. Error identification mode has also been added. This integrated function is helping to distinguish the failure status by applying “Short Current Protection”, “Under Voltage Protection” or “Thermal Shutdown Protection”.

ROHM is committed to further expand its lineup for a wide range of applications, including products optimized for the automotive sector. These products contribute to reducing application design load and power consumption while solving the social challenges such as environment protection.

Key Features

1. Achieves best-in-class low noise characteristics with low loss

Optimizing the built-in IGBT’s characteristics and soft recovery characteristics of the internal FRD reduces radiated noise by over 6dB (at peak comparison) vs standard products, making it possible to consider simplifying the noise filter typically required. At the same time, incorporating ROHM’s latest IGBT reduces power loss by 6% (fc=15kHz) compared with conventional products by decreasing both conduction and switching losses. The result is class-leading performance that delivers lower power consumption in a variety of equipment.

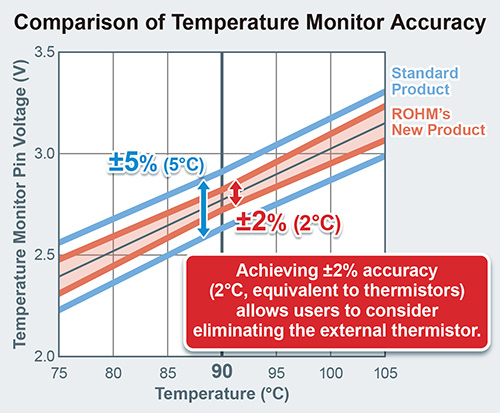

2. Dramatically improved temperature monitoring accuracy, making it possible to consider eliminating an external thermistor

ROHM’s new products provide a significant improvement over the ±5% (equivalent to 5°C at 90°C) of standard temperature monitoring functions, achieving ±2% (equivalent to 2°C at 90°C) equivalent to thermistors. This makes it possible to consider eliminating the external thermistor required with conventional high accuracy temperature monitors, reducing the number of external parts along with design load.

3. New built-in product identification function prevents mounting errors

Normally, part numbers printed on the molded package are difficult to recognize after mounting on the board, but a novel identification function included in the BM6437x series makes it possible to identify the product by measuring the impedance, preventing erroneous mounting (i.e. of competitor products with the same package type or parts with different current ratings).

Product Lineup

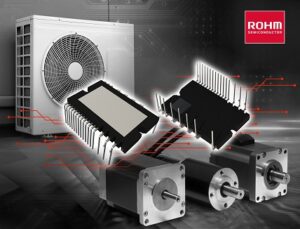

Application Examples

- Inverters for home appliances such as air conditioners, washing machines, and refrigerators

- Inverters for compact industrial equipment, including small-capacity motors for robots

- Other applications that utilize inverter control (i.e. compressors, motors)