Every modern ICE-driven vehicle comes equipped with a starter motor. It’s this secondary motor that prevents you from having to get out and manually cranking the car into life. But exactly how do they work, and what’s the difference between the various sorts of available motor?

What are starter motors?

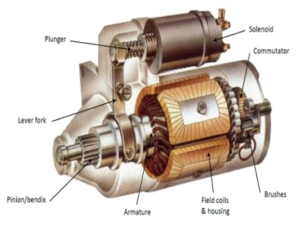

An internal combustion engine needs to be turning at speed to get the chain reaction started. As it does so, it’ll belch out spent exhaust fumes, and draw in clean oxygen to perpetuate the reaction. It’s the job of the starter motor to get the internal combustion engine into this state. It does this through electromagnetic means, coming equipped with a powerful solenoid magnet and a motor equipped with many lengths of coiled wire, which drive a pinion which in turn drives the engine. The whole process is started via an electromechanical switch located beside the steering wheel.

The starter motor is a small device, usually nestled somewhere between the engine itself and the transmission. Most motorists don’t need to know where the motor is, as it rarely needs to be replaced.

The Different Types

Starter motors come in several different sorts. The age and type of vehicle you’re driving will determine the kind that you have.

Inertia Starters

These are typically found on smaller vehicles. The motor here does not connect directly to the engine, but to a secondary flywheel. When this flywheel has gotten up to speed, the motor is disengaged, and the still-spinning flywheel is connected to the engine. Consequently, inertia starters can be much smaller – but it might take a long time for them to get up to speed.

Pre-engaged Starters

These represent the majority of modern starter motors. They keep the pinion in place using magnets, preventing it from being ejected as the motor spins. There’s a clutch in place to ensure that the starter motor drives the engine, and not the other way around.

Heavy Vehicle Starters

If you’re starting a much larger engine, then you need a different class of starter motor. Given that there are many different kinds of heavy vehicle, there are many different kinds of starter motor designed for this purpose. This specialization makes motors of this sort more expensive to replace. In some cases, this is simply a chunkier version of a standard pre-engaged starter. In others, we need several separate motors, each running in parallel in the same housing, to provide enough torque to drive the engine of a heavy industrial vehicle.

What about Electric Cars?

Electric cars run on electric motors, and thus there’s no need for an auxiliary motor to create a chain reaction. One of the advantages of this approach is simplicity when it comes to repairs and replacements, and a reduction in wear-and-tear.