Providing solutions that reduce EMI & power consumption in increasingly sophisticated ADAS

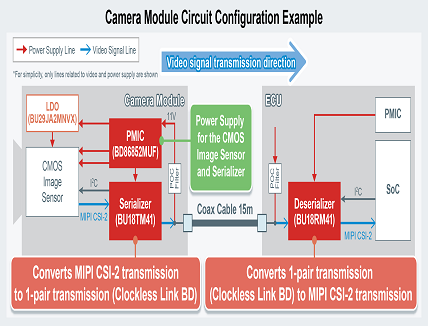

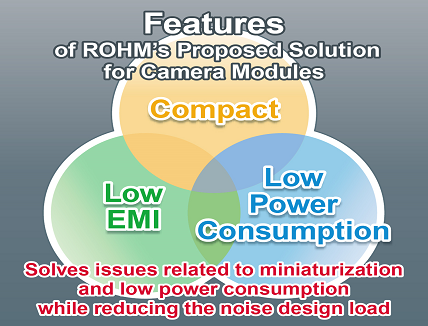

ROHM developed SerDes ICs (BU18xMxx-C series) and a PMIC (BD86852MUF-C) ideal for vehicle satellite camera modules for Advanced Driver Assistance Systems (ADAS). The new products not only solve issues concerning the miniaturization and low power consumption of modules, but also provide features such as low electromagnetic noise (EMI) that reduces development time.

ADAS applications are using a combination of devices that perform different sensing and distance methods, such as LiDAR, radar, sonar, and cameras. Among these, cameras play an important role in detecting objects and risk situations in the surrounding of the vehicle. Latest cars are equipped with up to 10 cameras or more per vehicle. Furthermore, as ADAS becomes increasingly sophisticated, the number of cameras is expected to rise together with camera performance. In order to accommodate this increase in the number of cameras – given the limited available space due to vehicle design requirements – there is a growing demand for smaller boards and vehicle satellite camera modules that consume less power.

ROHM solves these challenges by combining SerDes ICs with a new PMIC for cameras. Both products utilize a spread spectrum function to reduce EMI. This also simplifies EMI countermeasures, which often require significant man-hours during the design of automotive applications.

The BU18xMxx-C SerDes IC optimizes the transmission rate based on video resolution, making it possible to reduce power consumption by 27% over general products. At the same time, the built-in spread spectrum function reduces the EMI peak by 20dB, while an integrated video sticking detection function improves the reliability of the entire ADAS system by detecting frozen images.

The BD86852MUF-C PMIC (Power Management IC) for cameras is designed to optimally manage the power supply systems of CMOS image sensors from all major manufacturers. This allows voltage settings and sequence control to be performed with a single IC, reducing mounting area by 41% and contributing to the miniaturization of vehicle camera modules. In addition, a camera PMIC heat concentration distribution circuit can be configured to lower power consumption by achieving a high conversion efficiency of 78.6% that suppresses heat generation.

ROHM is committed to continuing to support the evolution of vehicles by developing products that reduce power consumption while delivering higher system reliability.

Key Features

ROHM’s BU18xMxx-C SerDes ICs and BD86852MUF-C PMIC are qualified under the AEC-Q100 to meet the reliability requirements of automotive applications. At the same time, we are developing new PMICs for cameras that comply with the stricter ISO 26262 process certification requirements and plan to ship samples of products that meet the ASIL-B safety level standard in spring 2022.

SerDes IC (BU18xMxx-C) Advantages

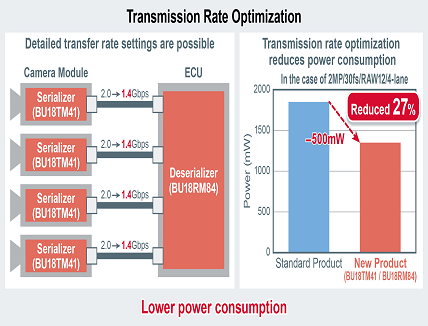

1. Optimized transmission rate contributes to lower power consumption in automotive camera modules

Typical SerDes ICs are characterized by a fixed transmission rate for each band. However, this method does not allow for detailed transmission rate settings, leading to greater power consumption loss. In contrast, the BU18xMxx-C is equipped with a function that optimizes the transmission rate based on resolution, not band.

This enables the transmission rate to be set more accurately than that of conventional products, delivering high efficiency operation that contributes to lower power consumption in vehicle camera modules. As a result, when adopted in applications that use 4 camera modules, power consumption can be reduced by approx. 27% over standard solutions.

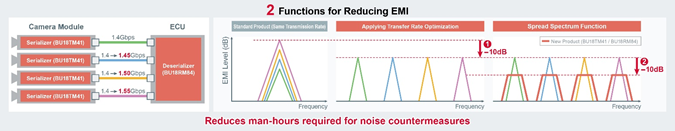

2. Transmission rate optimization together with spread spectrum function reduces the number of man-hours required for EMI countermeasures

Applying transmission rate optimization distributes the EMI peaks by shifting the transmission rate of each path a little at a time, making it possible to reduce EMI by about 10dB (Fig. 1). In addition, incorporating a spread spectrum function in both the serializer and deserializer ICs further decreases EMI by around 10dB (Fig. 2). This minimizes the number of man-hours required for EMI countermeasures, which often comprises a large part of the automotive design process.

3. Video sticking detection function contributes to improved reliability

A function is built in for detecting frozen images. In addition to verifying correct image transmission by comparing the MIPI CRC value from the CMOS image sensor to the deserializer, monitoring for stuck images is performed by comparing frame CRC value of the camera image with the previous and next values in the serializer. If the frame CRC value continues to match, an error flag is output to notify the IC in the subsequent stage that the image has frozen, improving the reliability of the ADAS system.

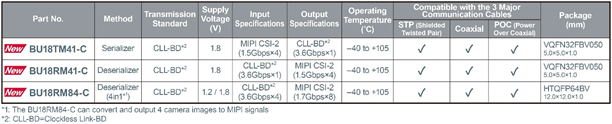

4. Complete lineup for all types of SoC and CMOS image sensors

The lineup consists of 3 part numbers: 1 serializer and 2 deserializers. All three models are compatible with the three main types of communication cables, allowing them to be used with a variety of CMOS image sensors and SoCs.

BD86852MUF-C Camera PMIC Series Advantages

1. Reduces board area by integrating functions optimized for CMOS image sensors

CMOS image sensors – a key component of vehicle cameras – not only require different drive voltage settings and sequence control depending on the manufacturer, but are typically configured utilizing many external components.

The BD86852MUF-C is equipped with pins for setting the sequence control and drive voltage of major CMOS image sensors. This significantly reducing mounting area over conventional solutions by requiring fewer external parts, contributing to smaller vehicle camera modules.

2. High conversion efficiency results in lower power consumption

This IC distributes heat concentration by utilizing an external LDO to supply power to the CMOS image sensor. Suppressing heat generation of the entire circuit achieves a high conversion efficiency of 78.6%, 4% more than standard products, which translates to lower power consumption in vehicle camera modules.

In addition, the distance between the CMOS image sensor and LDO can be shortened, decreasing disturbance noise in the power supply line to ensure stable power supply to the CMOS image sensor.

3. Built-in spread spectrum function reduces the number of man-hours required for EMI countermeasures

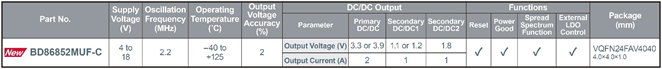

Three DC/DC converters are incorporated to supply the necessary power to camera modules. At the same time, sequence control is included that reduces the number of external components, along with multiple protection circuits such as a power good function for monitoring voltage conditions. This makes it possible to achieve providing high reliability.

Pricing / Availability

BU18xMxxC: In mass production

BD86852MUF-C: $2.10/unit (samples, excluding tax) / In mass production