Introduction

One of the more difficult challenges of time of flight (ToF) LIDAR is the high sensitivity required for the receive signal chain. Typically, a collimated (parallel rays of light) laser pulse is sent out to a spot. The advantage of a collimated laser source is that it limits light lost from divergence and keeps the spot size constant over distance. However, once the light hits an object, this light will bounce back in many directions—this is called scattering. The amount of reflected light back to the source is proportional to 1/R2, also called the inverse square law. At short distances, detecting an object is not as difficult. However, to detect objects at >100 meters, high gains are needed to detect the small amount of reflected light due to the inverse square law loss. One of the consequences of using high gains in the receiver is the effects on the signal chain from the ambient light. The Sun is a light source with a broad spectrum of wavelengths. LIDAR systems typically choose wavelengths of 900 nm and 1550 nm due to natural nulls of light from the Sun in these spectrums. Unfortunately, to detect faraway objects we have significant gains in the receiver, and the Sun’s ambient light can saturate the receiver even with these natural nulls in the spectrum. This effectively blinds the system and renders it useless. This article will explore solutions on how to mitigate the effects of ambient light for LIDAR receiver chains.

Basics

Taking a step back, a laser is used to send out a narrow pulse of light; this laser pulse hits a target, and the light reflects off the object. A detector is used to measure the time this reflection took to return. By knowing the speed of light and round-trip time of the laser pulse, the distance can be calculated. Generally, the higher the amplitude of the pulsed laser, the larger the return signal will be. For long-range LIDAR, eye safety from the power of the laser limits the range of modern systems. The area under the curve dictates the energy of the pulse, as shown in Figure 1. By going to higher peak power, the width of this pulse must be reduced to keep the area under the curve below the eye safety limits. Thus, our goal is to provide a high amplitude laser pulse with a relatively narrow width. In current LIDAR systems, the pulse widths are on the order of 5 ns and are moving to shorter pulse widths. Another aspect to consider for LIDAR is scattering. Typically, an avalanche photodiode (APD) detector is implemented to provide optical gain to combat the inverse square law problem. APDs are beneficial for the signal chain, since the transimpedance amplifier (TIA) is the limiting factor for noise in the signal chain. By applying gain in the detector, the system’s input referred noise is reduced. Keep in mind there are limitations in the APD, where too much gain will produce worse noise performance as it reaches breakdown.

LIDAR Challenges

As with any other engineering problems, there are trade-offs. The receive signal chain needs to have high enough bandwidth to detect the edges of ~5 ns wide laser pulses, and the capacitance of the detector needs to be small to not limit the TIA bandwidth. The smaller capacitance also helps the shot noise of the APD since they are proportional to one another. Sensitivity, bandwidth, and power must be balanced for real-world applications. Another challenge of having higher gains in the receive signal chain is the large dynamic range that comes with it. Modern APDs are reverse biased close to 300 volts to achieve these larger gains. The problem becomes apparent when a highly reflective object is very close to the detector. This large signal compounded with the relatively large gain of the APD can cause hundreds of mA to flow through the TIA. Most communications TIAs are not designed to survive this event, let alone recover within a reasonable time for the next cycle of the pulse. Fortunately, LIDAR-specific TIAs have built-in clamps to shunt the current and recover under 100 ns. Power is addressed by duty cycling and shutting down the unused channels. With these in mind, the last big problem is the DC photocurrents from the ambient light, and solving this is not trivial.

AC-Coupled vs. DC-Coupled Input

At first glance, a simple solution would be to AC couple the inputs to the TIA to block DC. Unfortunately, there are many pitfalls with this approach. The saturation recovery time will be compromised, blinding the system. In the event of a large pulse from a close object, the AC capacitor will be charged. The TIA can only inject a small amount of current into the AC cap because the feedback resistors, which are on the order of 10 kΩ to 100 kΩ, limit the current. Depending on the value of the capacitor, the RC time constant is very large and can take hundreds of µs to recover. This is unacceptable, since typically 2 µs of time is allocated for 100 m detections, and we will miss the signal from the farther objects. Another pitfall of AC coupling the TIA is the repetition rate of your laser source. When you AC couple the incoming pulses, the pulses will be averaged on the AC cap. The detector’s signal is unipolar and will slowly charge the AC capacitor. There will be a DC offset produced on this capacitor. This systematically reduces the linear range of the TIA, and the DC offset will change based on repetition rate and amplitude of return signal. A more detailed analysis of AC input coupled TIA is addressed in the “How to Effectively Design and Optimize the TIA Interfaces of LIDAR Systems” article. Fortunately, a DC-coupled input avoids all these nuances and secondary effects, but at a cost of added complexity. An effective method for canceling this current is by incorporating a closed-loop circuit to inject opposite current into the input of the TIA.

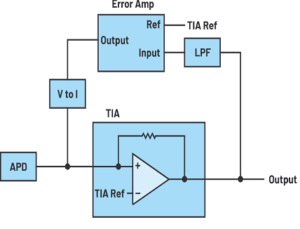

DC Cancel Circuit

Figure 2 shows the block diagram of how to implement an analog closed loop to cancel the DC input currents. The job of the error amp is to look at the output of the TIA and to inject an opposite current into the input of the TIA. It compares and servos the output to match the TIA’s reference. It is best to use the TIA’s reference to derive the error amp’s reference for two reasons: to match the output’s reference, and to ensure the PSRR is conserved for the TIA. To save on power and cost, a lower bandwidth amplifier should be used for the error amplifier’s circuit. A low-pass filter is recommended for the error amplifier’s input since you do not want the fast pulses to couple back into the input.

Figure 3 shows the DC cancel circuit for the LTC6560. Nominally the output of the LTC6560 sits about 1 V DC when there is no input current into the TIA. Therefore, a resistor divider is needed from the reference to match this voltage, dividing down the reference nominal 1.5 V to match the output 1 V. R1 and C1 create a low pass of about 10.6 kHz; this helps to minimize the amount of noise injected into the LTC6560 from the error amplifier. This low pass will be the dominant pole for this loop and can be adjusted for different bandwidth requirements. A simple integrating error amplifier circuit is used to servo the output of the LTC6560 to 1 V; keep in mind 1 V is the nominal output voltage when there is no current on the LTC6560. R2, a 20 kΩ resistor, is a simple implementation to convert the output of the LT6015 to a current. The value of this resistor and the maximum swing of the op amp will set the max current based on the LT6015 output swing. Since the LT6015 is not a rail-to-rail op amp, the max DC cancel will be limited to be the difference between the max swing of the LT6015 and the input self-bias voltage of the LTC6560, which is nominally 1.5 V. This works out be about 3 V and will give us a maximum DC cancel current of 150 µA.

Figure 4 and 5 show an LTspice® simulation of the LTC6560 DC cancel circuit. Notice that V2 is used in the simulation to set the reference of the integrating error amp. This is used to help the circuit simulate and establish a deterministic starting voltage.

This DC cancel circuit can be used with the LTC6561 as well. You can save three LT6015s by using four output resistors to inject the current into each channel, as shown in Figure 6. One thing to note is we are now creating a path that can couple the channels. However, 40 kΩ of resistance has a minimal impact on the channel-to-channel isolation. Lastly, the channels should be very similar in DC input currents since the error amp cannot change drastically between channels. This circuit will benefit a system where all the optical channels are close to one another.

Results

A proof of concept board was made to create a more compelling article and to verify performance. This is shown in Figure 7. As expected, the DC cancel circuit is dominated by the parasitic elements of the board routing and components. The circuit increases the integrated noise from 64 nA rms for the non-DC cancel circuit to 66 nA rms for the DC cancel circuit integrated from 100 kHz to 200 MHz. Figure 8 shows the measured input referred noise densities with and without the DC cancel circuit. The APDs were removed from this circuit to find the noise floor without the capacitive loading to the TIA. This produced an integrated noise of 59 nA rms for the non-DC cancel circuit and 60 nA rms for the DC cancel circuit. However, the circuit is intended to be used with a detector and should include the capacitance into the performance of the circuit.

Conclusion

AC coupling the inputs of the LTC6560 and the LTC6561 may pose some challenges. Ultimately, there are limited cases where AC coupling can be implemented with minimal impacts to the circuit’s performance. In modern LIDAR systems, to maximize system performance, the proposed DC cancel circuit can provide the maximum recovery time performance without impacting the circuit noise. The trade-offs for this performance are complexity with the layout and increased power consumption of the integrating error amplifier.