- Light intensity control with Mean Well products

- Mean Well – perfect solutions for LED lighting

- Mean Well – LED drivers perfect for indoor use

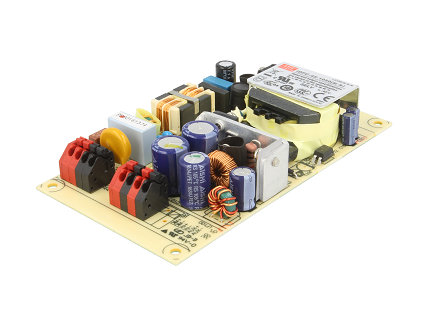

- Open-frame LED drivers from Mean Well

- Drivers for light fixtures

Powering LED lighting requires constant current flowing through the connector of a single LED or a group of them. This requirement has to be fulfilled, no matter the value of the LED threshold voltage, as it’s going to change along with the connector temperature changes. Only in simple signaling systems LEDs can be powered by a current-limiting resistor, however, using such a solution in lighting might significantly lower its durability. That is why a “regular” power supply or driver might not be enough to power LEDs working in lighting systems.

In actual applications, LEDs work in a constantly changing temperature and they warm up as the current flows. The p-n junction has a negative temperature coefficient, which means that its threshold voltage decreases as the temperature rises, which causes the LED resistance to decrease, too. A “regular” power supply with decrease in the load resistance is going to keep the voltage constant and to increase the current. This is not dangerous to the LED if it works with a significant power reserve, however, an increased loss of power in the LED is going to occur. Still, these increased power losses might not damage the LED, but they will significantly limit its durability. What’s more, it can lead to the thermal runaway. It happens when the current flowing through the p-n junction is increased in order to obtain the highest light intensity. Even with a short rise of the ambient temperature, that increased current is going to cause the LED junction’s temperature to rise. The heated p-n junction is going to conduct more current, which is going to cause the exponential rise of its temperature, even though the external factor is gone. And it goes on until the LED is damaged.

Light Intensity control with Mean Well products

What distinguishes Mean Well from other driver manufacturers is the quality of the design and increased reliability of the products. All of the processes, from the concept to the mass production, are subject to stringent procedures meant to ensure security, efficiency, and quality, so the end user can be sure that they are receiving a suitable product, with increased durability and a long life, compliant with most standards and requirements. Mean Well has worked hard for its reputation, offering products of high quality, in attractive prices, and also a wide range of standard products. In recent years, Mean Well has focused on the mass production of LED drivers with the output power from 12 to 320W. Below, you can find a short description of the product lines.

Just by looking at the initial problems that can arise while designing LED lighting, you can see that it requires solving a lot of technical difficulties. One of the most important problems is the need to enable heat dissipation that is independent of external conditions, as the temperature (and the power loss caused by it) is what influences LED durability the most. Another issue is the requirement of meeting the EMC and safety standards. It’s worth noting here that until some time ago LEDs used to be installed mostly indoors, but now you can see them everywhere – from vehicles to buildings. Therefore, the best choice is to go with proven, ready-made solutions and by doing so reduce the time between the development of the concept and the introduction of the product on the market.

PWM light intensity control involves passing, through the LED, certain direct, steady current that is periodically turned on and off at a pre-set frequency. Change in the light intensity is achieved by way of a change in the square wave duty cycle powering the LED. Human eye can’t see the high frequency light flicker. Instead, it averages the light intensity, and in this way perceives the change. The biggest advantage of this method is the precision of the intensity regulation and a wide range of possible settings, which is especially important for RGB multicolour LEDs. Additionally, the LED works in constant power conditions, which increases its durability. One drawback is the necessity to design an elaborate power supply that would be capable of fast switching on/off with certain precision. Such a source is also going to cause higher EMI, which can restrict the length of connection cables. Also, the influence of their inductance and capacitance must be taken into account.

Mean Well – perfect solutions for LED lighting

The range of Mean Well products for lighting applications is huge, their quality being the result of over 35 years of the company’s experience and confirmed by multiple safety and quality certificates. If there is a demand for any LED lighting system, it can definitely be powered and controlled using Mean Well products.

The range of products is very wide, which is why we are only going to present the possibilities offered by a few selected series of drivers. When choosing a product for your specific use, make sure to use the filters that will help you find drivers with proper parameters. In this way, it will be much easier for you to pick a driver of the relevant power, work mode, enclosure, voltage power range, and available functions. While making a choice it’s also worth looking into available EMC and security certificates in order to avoid issues with the technical acceptance and functioning of the target LED lighting application.

Mean Well \– LED drivers designed for indoor use

It may seem like drivers created to power indoor lighting systems are easy to design. Unfortunately, this is wrong, since the devices are dedicated for mass use and therefore they must comply with safety standards expanded to include unprofessional mass users. Because of the mass use, they also have to comply with increased EMC requirements.

IDL series includes two types of drivers with different markings. IDLV products are intended for indoor applications. They offer constant output voltage with PWM light intensity control. IDLC drivers, in turn, offer constant output current and are suitable for light fixtures. The input voltage ranges from 90 to 295V. The design is compliant with the II/2 class requirements. They are equipped with a dimming function, but it must be noted that only the DLC-45/65 series can be dimmed using DALI. Auxiliary voltage output can be used to power a cooling fan or a connected IoT device. 25, 45, and 65W variants are available.

PWM series are constant voltage LED drivers with a regulated duty cycle at the output. They are designed mainly to power LED strips. The 40, 60, 90, 120, and 200W variants are available. They are equipped with a 3-in-1 dimming input and can be controlled using DALI. Their input voltage ranges from 90 to 305V AC. They are designed in compliance with the 2/II class requirements.

Switched-mode PWM-120-24 driver

Mean Well open-frame LED drivers

IDP series drivers are available in two variants: constant voltage (IDPV) and constant current (IDPC). They are all equipped with an analogue 0-10V dimming input and with dimming through the DALI interface. Input voltage is 90…295V or 90…305V AC, and the series is compliant with the II/2 class requirements. 25, 30, 45, 65, 80, 100, 160, and 240W variants are available.

Drivers for light fixtures

The drivers mounted inside a light fixture are a special type, because of the variety of fixtures and due to the various operating conditions depending on the application. For example, if you want to use the driver in a street fixture, you will have to combine a significant electrical load and a wide range of input voltage with resistance to atmospheric conditions, a wide range of ambient working temperature. You would also have to provide PFC and efficient cooling. All that in relatively small enclosure, heated by sunlight and power losses in the LEDs.

ODL series drivers are designed in compliance with the IP67 class. The ODLC series are constant current (CC) drivers, while the ODLV series are constant voltage (CV) drivers. They are both equipped with a 0…10V dimming input, and ODLC can be dimmed using DALI. The supply voltage ranges from 90 to 295V AC, and the drivers are compliant with the II/2 class. They are also equipped with a 12V auxiliary voltage output that can be used to power external devices, e.g. an IoT interface. 25, 45, and 65W variants are available.

The original text is prepared by TME.