We all have experience with sensors. As design engineers, we use temperature sensors—humidity, pressure, force, stress, touch sensors, etc.

What about human sensors?

In today’s world of occupancy-sensitive locations and safe distancing requirements, the need to maintain safe person-to-person space in retail, commercial, industrial, civic, factory, and sporting settings has become critical. We have always seen maximum occupancy signs in clubs and restaurants, but we’re now at a more serious level.

People detection has always been a low-level technology until now. Alarm systems use open and closed contacts from switches, magnets, or infrared (IR)/microwave motion detectors for recognizing security threats. Still, these are not resolute enough to count humans and exhibit false alarms when animals pass by.

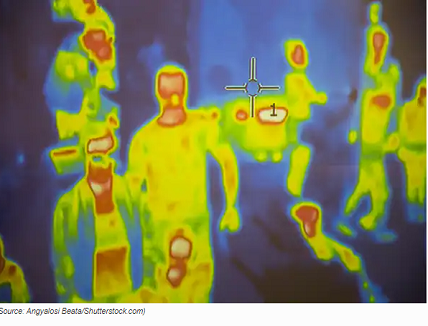

Video sensors can be used with artificial intelligence to discern specific shape types and differentiate between dogs and people, for example. Still, more constant video surveillance doesn’t sit well with the public. As an added challenge, video, AI, and high-power processors are expensive and complex for such a simple task.

So, what happens when you take a low-resolution video sensor array and tune it for heat detection? Charge-Coupled Device (CCD) image sensors are already sensitive to IR, so the human detector is born with a few minor tweaks. That’s what Panasonic has done with its family of Grid-EYE® sensors for human detection.

When coupled with the right software, Panasonic Grid-EYE® sensors allow all public places to monitor heat differential over a wide two-dimensional plane of detections, and discern, count, and measure the distance between two thermally emissive objects. It also can all be conducted without any human movement.

Panasonic Grid-EYE® sensors will alert security or employees in various settings when people are too close together, when too many people are in one location, or when people stray into unauthorized areas. This can all be done without recording video images that can identify someone, so it quells any security concerns, too.

Designing With Thermal Imaging Sensors

Both narrow-angle and wide-angle board-mount thermal array sensors are already available off-the-shelf. For example, the AMG8854M01 is a surface-mount modular narrow-angle 8px x 8px (64-pixel) high-precision micro-electromechanical system (MEMS) IR array that operates on standard 5V power supplies and connects using a simple I2C 5-pin connector (Figure 1). This easily interfaces to virtually any micro to read thermal levels in each block (from -21°C to 80°C) with an accuracy of ±3°C.

Figure 1:This narrow-angle modular thermal array sensor allows designers to quickly test and evaluate the 8px x8px thermal matrix using a simple 5-pin I2C connector. (Source: Mouser Electronics)

The AMG8834, a 3.3V low gain version, I2C-based 8×8 thermal array in a surface-mount reflow package, is also available. Although only two I2C slave addresses are typically supported by multiplexing the clock, it is relatively easy to implement multiple I2C ports on a micro, which is what you would want to do since each read is 64 12-bit thermal values. The device offers selectable 1 or 10 frames per second rates when scanned using the I2C interface.

Two versions of this sensor are available; low-gain and high-gain, which can help match the sensor with the environment. The high gain has better accuracy but a narrower temperature detection range, while the low gain has a lower accuracy but a wider temperature detection range. The thermally sensitive pixels can be read indirectly without the need for an external IR illuminator. IR illuminators are typically needed for the shorter wavelength discrete IR light sensors.

To allow you to start testing right away, a development tool is also available. The MIKROE-2539 provides breakout board functionality for the Grid-EYE sensors (Figure 2). Although, the interface is simple enough that an engineering lab could get the sensor up and running quickly using a few I/O pins and a power connection (Figure 3). Note: An interrupt is available for detection notification when an image plane is ready to download.

Figure 2: A modular development board is also available for test and evaluation. (Source: Mouser Electronics)

Figure 3: A simple interface allows a two-wire I2C port to read and control the Grid-EYE sensors. An interrupt and select line make it easy to implement a larger array. (Source: Mouser Electronics)

Suppose 64 pixels do not offer enough detection range. In that case, Panasonic offers a smart interpolation solution that helps expand the working data points while only using a single Grid EYE to significantly improve accuracy within the detection range window. Individual sensors are ideal for entry and exit zones and can accurately detect when a human has passed through a zone of detection. Larger offices and buildings needing full coverage must either distribute sensors at strategic locations or combine several sensors into a larger array.

Although one of the most critical applications currently is that of human detection, these sensors span various other beneficial uses. For example, they can be used in agricultural settings to detect how many cattle leave a pen to graze and how many return. They can also serve in a manufacturing test environment to look for systems that are overheating and not operating up to specification. Debug systems can also take advantage of these as lower-cost alternatives to FLIR cameras.

Conclusion

The heat is really on when it comes to sensors. With simple sensor technology, businesses can tap into simple yet advanced detection technology to prepare for crowds, eliminate crowds, monitor equipment, create comfortable work temperatures, and ultimately continue safe and productive operation.

The blog was first published in Mouser Electronics.