ROHM has signed a joint development agreement with Mazda Motor Corporation (Mazda) and Imasen Electric Industrial Co., Ltd., (Imasen) for inverters and SiC Power Modules to be used in the electric drive units of electric vehicles, including e-Axle.

As the ‘heart of the EV’, e-Axle integrates a motor, reduction gearbox, and inverter into a single unit that plays a large part in determining the driving performance and power conversion efficiency of electric vehicles. SiC MOSFETs in particular are expected to improve efficiency even further.

ROHM will carry out joint inverter development for e-Axle by participating in a ‘cooperative framework for the electric drive units development and production’ with companies such as Imasen and led by Mazda. At the same time, ROHM will contribute to the creation industry-leading compact, high efficiency electrical units by developing and supplying advanced SiC power modules that provide improved performance.

ROHM SiC Power Modules

Through this collaboration, ROHM will develop even more competitive SiC MOSFETs and modules by working backwards from the finished vehicle to understand the performance and optimal drive method required of power semiconductors.

Besides creating new value through mutual understanding between car and device manufacturers, the three companies also support technical innovation in the automotive field and contribute to a sustainable society by leveraging extensive knowledge, technologies, and products garnered on a global basis.

Ichiro Hirose, Director and Senior Managing Executive Officer; Oversight of R&D, Cost Innovation and Innovation, Mazda Motor Corporation

‘We are pleased to collaborate on the development and production of e-Axle with ROHM, who hopes to create a sustainable mobility society through outstanding semiconductor technologies and advanced system solution development capabilities, to co-create a new value chain that directly links semiconductor devices and vehicles in both directions as electrification brings us closer to carbon neutrality. By partnering with like-minded companies, Mazda is committed to injecting ‘driving pleasure’ into every product – including electric vehicles.’

Katsumi Azuma, Director and Senior Managing Executive Officer and COO, ROHM Co., Ltd.

‘We are extremely pleased to work together on the development and production of e-Axle with Mazda, who is committed to providing ‘driving pleasure’ that expresses the inherent appeal of cars. Through this partnership, we hope that by reflecting the true demands and requests in our products we can develop automotive systems that contribute to decarbonization while allowing us to gain a deeper understanding of Mazda’s goal of creating cars that are sustainable with the earth and society. As the role of semiconductors in the automotive market continues to grow, ROHM will strive to manufacture high quality products and contribute to the creation of a sustainable mobility society by offering a wide range of solutions.’

Reference Information

As semiconductors, ROHM’s core products, play an increasingly important role in achieving a decarbonized society, improving the efficiency of motors and power supplies in particular – which are said to account for most of the world’s electricity consumption – has become a major mission of ROHM.

Against this backdrop, ROHM has formulated a management vision for 2020: ‘We focus on power and analog solutions and solve social problems by contributing to our customers’ needs for “energy savings” and “miniaturization” of their products.’ And to further contribute to society, ROHM will clarify the direction ROHM should take while raising awareness among all Group employees.

For electric vehicles, more compact, efficient, lightweight electric systems are being developed with the goal of becoming carbon neutral. Especially for electric vehicles, the inverter, which plays a central role in the drive system, needs to be made more efficient to extend the cruising range and reduce the size of the onboard battery, increasing the expectations for SiC power devices.

As the first supplier in the world to begin mass production of SiC MOSFETs in 2010, followed by the first full SiC Power Modules in 2012 and trench-type SiC MOSFETs (3rd Gen) in 2015, ROHM continues to develop SiC device technologies ahead of the industry.

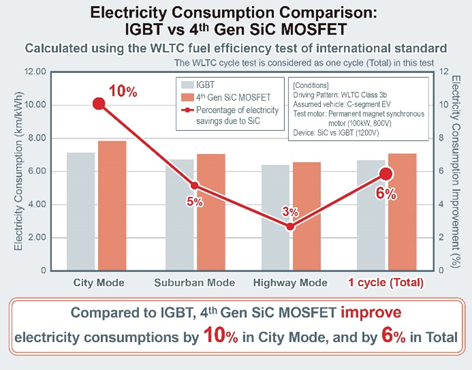

In 2020 ROHM completed development of its latest (4th Gen) SiC MOSFETs that deliver improved short-circuit withstand time along with the industry’s lowest ON-resistance, making it possible to extend the cruising range of electric vehicles by reducing power consumption 6% vs IGBTs (as calculated by the international standard WLTC fuel efficiency test) when installed in the main inverter. In addition to bare chips, ROHM is currently developing products with discrete packages, and this collaboration will allow us to develop and offer power modules equipped with the latest (4th Gen) SiC MOSFETs.

Supporting Information

An overview of SiC power devices that includes SiC MOSFETs, SiC SBDs, and SiC Power Modules (together with various support content that provide an introduction and enable quick evaluation of 4th Gen SiC MOSFETs) can be found on ROHM’s dedicated SiC page below. Feel free to take a look.

SiC Power Devices & SiC Power Modules

https://www.rohm.com/products/sic-power-devices

Supporting Content for ROHM 4th Gen SiC MOSFETs:

- Introductory, product videos

- Application notes (product overview and evaluation information, traction inverters, onboard chargers, SMPS)

- Design models (SPICE, PLECS, 3D CAD data of packages, footprints, etc.)

- Simulation circuits of key applications (ROHM Solution Simulator)

- Evaluation board information