The Covid pandemic has significantly impacted lead times on everything from passive components to wireless modules, meaning even the best-prepared engineering and supply chain teams were caught off-guard.

While some components are easy to substitute, discrete semiconductors and integrated circuits are less so because they are more complex and closely linked to a design. This article provides some guidelines for redesigning when faced with a component shortage.

Sever Supply Challenge

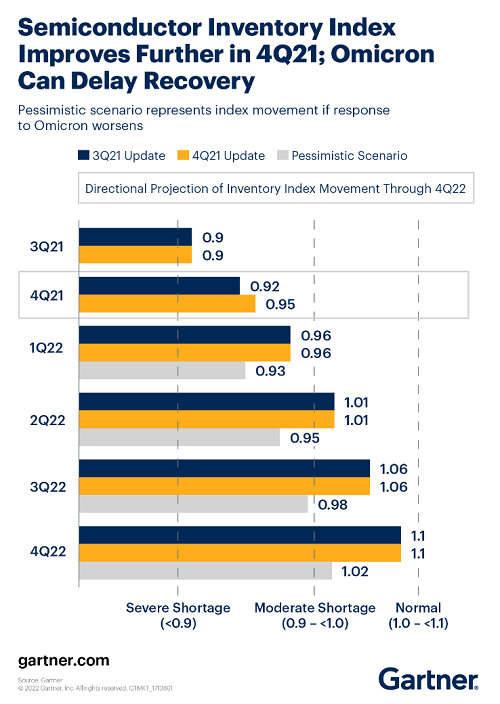

While in 2021, the electronics industry faced severe supply bottlenecks, according to Gartner research, by Q4 2021, these were beginning to ease with manufacturing staff returning to work, and production volumes were growing steadily. While demand still exceeds supply, Gartner suggests that the situation will improve further (see Figure 1). In the meantime, many engineering teams have no option but to consider redesigning current products.

Understanding Risks and the Need for Collaboration

Product designs include many passive components and fewer ICs and modules like microcontrollers, power management (PMICs), sensors, and wireless transceivers. Passives are usually commodity purchases (unless they have unique features). However, some types of capacitors—for example, multi-layer ceramic capacitors (MLCC)— can sometimes be ‘on allocation.’

Close collaboration between engineering and purchasing teams has been critical as the electronics industry has worked through component shortages. Continuous reviews of second-source or third-source candidates require detailed analysis of component values, physical size, form factors, and certifications.

A well-planned design for manufacture (DFM) strategy should also address difficult-to-second-source components, like microcontrollers. These are literally “embedded” in a design, so finding another microcontroller with the same features may not be possible and necessitate a more serious alteration to the design of a product. This requires an evaluation of the product’s architecture and deciding whether to stay with the same microcontroller supplier and opt for an alternative part or to change vendors completely. The implications of these decisions can be serious and require careful consideration. Before doing so, it is essential to check with suppliers, and their authorised distributors, as new inventory may become available within a reasonable timescale.

Design Auditing

Deciding to change a microcontroller can have the most significant impact.

Issues to review when migrating a microcontroller platform include:

Code portability: Can the code be quickly and easily migrated to an alternative device? Is the software language hardware-dependent? Does the code use vendor-specific hardware abstraction routines to send information through peripheral ports to other devices? Well-structured code with global port assignments and declarations can significantly reduce the requirement to rewrite code.

Libraries, device drivers and other firmware: Vendor-supplied device drivers and libraries help to accelerate application development with any MCU. For example, using a library function to control a MEMS accelerometer allows the engineer to work on the end application rather than the details of the internal workings of the sensor. However, a library may not exist for all languages or use specific functions on the host MCU.

Cross-platform RTOS/Operating Systems: Many embedded systems may use a real-time operating system (RTOS) for scheduling and managing time-dependent activities, so if your current design uses an RTOS, then you need to find out what other microcontrollers support it.

Microcontroller platform decisions to ask include:

MCU architecture: What architecture does your current device use? The instruction set architecture is also essential —Arm, 8051, AVR, RISC-V? Maybe your current vendor can provide a device with the same internal architecture that is readily available. Layout changes are required if moving to a device with a different package, which can mean a costly board rework. An ideal but unlikely scenario would be to identify a pin and software-compatible alternative to your current MCU.

MCU functionality: Most microcontrollers support many peripheral functions, including analogue-to-digital converters, clocks, counters, and controllers and many now also have security features and cryptographic accelerators. Connectivity ranges from simple GPIO to more complex protocols like USB, CAN, and Ethernet. The pin arrangement for these functions can also significantly affect the board layout.

The power consumption of a potential alternative microcontroller must also be considered, including how it behaves in sleep mode, as prolonging battery life is essential for many portable and hand-held devices,

Toolchain support: Developers use an integrated development environment (IDE) to program and debug microcontrollers, which may also be a factor. Commercial IDEs may require a change of software license for a different MCU. Changing MCU and IDE can affect product development and how post-design support is provided.

Other Considerations

PCB rework and redesign: The amount of board redesign required due to changing a microcontroller depends on the product’s features and can involve a lot of engineering effort and expense. Therefore this can represent an opportunity to simultaneously update a product’s specifications and incorporate new design features.

Regulatory compliance and safety certifications: Even minimal changes to hardware and software could make a product non-compliant with certifications and thus require lengthy product testing and re-engagement with a product testing laboratory.

Cloud and wireless connectivity: Many products connect wirelessly to the cloud or a smartphone app, and hardware changes might require changing the software libraries or wireless module drivers.

Interfacing with 3rd party ecosystems: If your product connects to the IoT/IIoT (Internet of Things/Industrial Internet of Things) or home automation applications, it would be wise to check if design changes will require re-certification for third-party applications.

Detailed Analysis is Key to a Successful Migration

While market conditions appear to be more favourable over the coming year, product manufacturers must regularly review supply chain risks and their potential impact on production schedules.

This article has highlighted some of the challenges and issues facing end-product manufacturers considering (or are forced to consider) moving to another microcontroller platform.

Engineering teams should maintain ongoing contact with their supplier to fully utilise tools, forecasts, and insights from component distributors and providers.