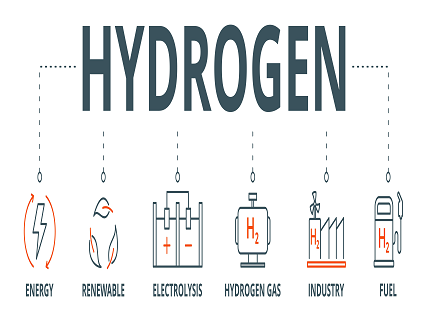

Electrolysis, in simple terms, is breaking down chemical compounds into their elements using electric current. In the past, it was used for metal extraction, electroplating, and water treatment. Today, electrolysis technology is at the forefront of the clean energy revolution, as it offers a promising solution for producing hydrogen—a versatile and environmentally friendly fuel.

With the growing demand for sustainable energy sources, researchers have been striving to develop more efficient and cost-effective electrolysis technologies. Among the various companies contributing to this innovation, KNF has been particularly influential in the field of diaphragm pumps and systems, which play an important role in electrolysis technology. As advancements in electrolysis continue, we can expect these technologies to be mainstreamed—sooner than later.

This article will delve into six groundbreaking advancements shaping the future of hydrogen production.

- High-Temperature Electrolysis (HTE)

High-temperature electrolysis (HTE) is a method that uses special devices called solid oxide electrolyzer cells (SOECs) to split compounds, like water, into their basic elements, such as hydrogen and oxygen. In simpler terms, HTE takes advantage of high temperatures and waste heat to perform electrolysis more efficiently and sustainably.

HTE can be integrated with renewable energy sources, such as concentrated solar power or geothermal energy, providing the high temperatures required. This combination allows for hydrogen production using clean energy, reducing greenhouse gas emissions, and supporting a more sustainable energy future.

HTE can be used in power-to-gas systems, which convert surplus electricity from renewable energy sources into hydrogen. Hydrogen can be stored and later used to generate electricity when needed, reducing the reliance on non-renewable fossil fuels.

HTE can be combined with carbon capture technologies to produce synthetic fuels or chemicals. In this process, captured carbon dioxide is combined with hydrogen produced through HTE to generate hydrocarbons, such as methane or methanol, providing a sustainable method for carbon utilization.

- Electroplating In Electronics

Electrolysis has several applications in electronics, both in manufacturing processes and developing certain electronic components. Electroplating, a process that uses electrolysis, is used to improve the conductivity of electrical contacts, enhance corrosion resistance, and create decorative finishes on various components, like connectors and printed circuit boards (PCBs).

Electroplating connectors and contact points with metals with high electrical conductivity, such as gold, silver, or copper, enhances the flow of electrical current, ensuring reliable connections and better device performance.

Electronic components are often exposed to various environmental conditions that could lead to corrosion, affecting their functionality and lifespan. Electroplating a protective layer of a corrosion-resistant metal, like gold or nickel, onto the components helps to prevent corrosion and prolong the life of the devices.

- Hydrogen Refueling Stations (Modular Electrolysis System)

Modular electrolysis systems are designed to be scalable and adaptable, allowing for easier implementation in various settings. Modular electrolysis systems offer a versatile solution for hydrogen production, making the technology more accessible and flexible for multiple applications, from remote or off-grid locations to industrial settings.

Modular electrolysis systems can be deployed at hydrogen refueling stations to supply hydrogen for fuel cell vehicles. This supports the growth of hydrogen-based transportation infrastructure and encourages the adoption of more environmentally friendly cars.

- Artificial Photosynthesis

Inspired by nature, scientists are developing electrochemical cells that mimic the process of photosynthesis to produce hydrogen and other useful chemicals. This technology has the potential to revolutionize hydrogen production by using sunlight and water more efficiently than traditional electrolysis methods.

- Battery Development And Recycling

While electrolysis is not directly used in the operation of modern batteries, it plays a significant role in developing and producing some battery types. Additionally, some aspects of electrolysis can be observed in the chemical reactions occurring within the batteries.

Electrolysis plays a crucial role in developing and functioning some types of batteries, such as nickel-metal hydride (NiMH) and nickel-cadmium (NiCd) batteries. These batteries use an electrolytic process to store and release electrical energy.

Research in advanced batteries, such as metal-air or redox flow batteries, involves investigating various electrochemical processes, including electrolysis. Understanding and optimizing these processes can help improve the efficiency, capacity, and lifespan of the next generation of batteries.

Electrolysis plays a role in recycling certain types of batteries, such as lead-acid batteries. During recycling, electrolysis can recover valuable metals like lead or separate different battery components for further processing.

- Supercapacitors

Electrolysis is involved in operating some supercapacitors, which are energy storage devices with high power density and rapid charging and discharging capabilities. These devices use electrolytes to store and release electrical energy, making them valuable in various electronic applications, such as power backup systems and energy management.

One of the key applications of supercapacitors is their ability to provide short-term power backup in the event of power outages or during periods of high demand. They can be used in uninterruptible power supply (UPS) systems for data centers, hospitals, and other critical infrastructure.

Takeaways ( Electrolysis Technology )

In a world with dwindling sources of metals and energy supply, advances in electrolysis technology are lifesaving. Electrolysis technology is crucial for a sustainable energy future, and these six advancements demonstrate the exciting potential of this field.

As researchers continue to study the various potentials of electrolysis, we can expect hydrogen production to become more efficient, cost-effective, and environmentally friendly, paving the way for widespread adoption in various industries and applications.