Chromatic 3D Materials is a company that has made a name for itself in the industry through its 3D-printed elastomer parts, which have enormously high strength while remaining flexible, affordable and sustainable within the manufacturing process. In addition to manufacturing flat O-rings, L- and T-seals, as well as various types of flange seal, Chromatic 3D particularly focuses on the production of sophisticated components that are tailored for specific customers. A combination of additive processes and chemical reactions forms the technical basis for these manufacturing operations. Bart Engendahl, the managing director of Chromatic 3D Materials GmbH, gives an overview of how the successful cooperation with engineers from ViscoTec’s Business Development team began – resulting in a fruitful collaboration that continues to this day.

When did you first meet the Chromatic 3D Team?

Bart Engendahl: We met Felix Gruber from ViscoTec’s Business Development Additive Manufacturing division at the Formnext trade fair in 2019. Together with my colleague Cora Leibig, who is the CEO of Chromatic 3D Materials Inc., we got talking to one another for the first time there.

Was there a specific reason for this, or was it just out of pure interest to begin with?

Bart Engendahl: No, there was in fact a reason for the encounter: At Chromatic 3D, we were on the hunt for an extruder. Specifically, one that would be compatible with 3D printing control software. We also wanted it to be able to dose two-component polyurethane, which is one of the things we talked a lot about with Felix Gruber from ViscoTec.

So how did Chromatic 3D approach fluid handling previously?

Bart Engendahl: Among other things, our engineers had carried out tests with piston-driven and pneumatic dosing systems. But we weren’t particularly happy with those.

Do you know what the results of those were, and what conclusions were you able to draw from how they turned out?

Bart Engendahl: The biggest sticking points in those tests were the accuracy and the flow rate consistency. These weren’t satisfactory for Chromatic 3D and for what we were aiming to achieve.

What solutions was ViscoTec able to introduce in this respect?

Bart Engendahl: The ViscoTec engineers from the Business Development division – including Simon Kasböck – immediately recognized the potential of their printheads for two-component materials. These achieve a theoretical volume flow between 0.03–6.00 ml/min per printhead half. A wide variety of materials can be dosed with these, such as silicones, polyurethanes, epoxy resins, acrylates or polyester resins, to name just a few examples.

In addition to the already mentioned seals, are there other products that are particularly suitable for manufacturing by Chromatic 3D?

Bart Engendahl: One niche that’s successfully served by Chromatic is the manufacturing of parts that presently only have little demand on the market, yet are absolutely crucial for the operation of machines or plants. The possibility of having these “spare parts” printed quickly saves the responsible parties in the industry a lot of time and money. This is illustrated, for example, by a polyurethane buffer that had to be manufactured for a bogie originally made in 1967. With no material data and only an old 2D drawing, it would have been far too expensive to attempt to reproduce such a part. Taking an equivalent component as a basis, Chromatic 3D created a 3D model, printed it using high-quality material and tested it. This meant that the customer was able to obtain a replacement part quickly and at low cost.

So how does ViscoTec contribute to these processes?

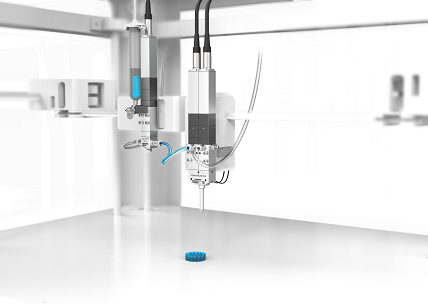

Simon Kasböck: We’re not just a collaborative partner, but also a technology supplier and a troubleshooting support service. Chromatic 3D, of course, manufactures its components exclusively on 3D printers. And they don’t just develop these in-house, but also build them there. Our vipro-HEAD 5/5 printheads form part of these sophisticated 3D printing technologies. We at ViscoTec have assisted Chromatic 3D in integrating the vipro-HEADs into their RX-Flow™ printer technology. Naturally, we’re also looking out for which of our customers could benefit from Chromatic 3D applications.

Can you say a bit more about the material and the technology?

Bart Engendahl: We created both the RX-AM™ material and the technology platform for the additive manufacturing. The resins that are used on the platform are developed in-house. The resin development is something that distinguishes Chromatic 3D from other market participants – it’s almost a unique selling point for the company. Seals are in demand for applications such as the construction of machines, trains or cars and even for airplane interiors. Chromatic 3D therefore satisfies requirements with regard to flammability that are mandatory to observe in the aerospace industry.

Why is dosing equipment so important for these resins?

Simon Kasböck: Simply put, the quality of the end product from Chromatic 3D is wholly dependent on a reliable and precise fluid handling process. Only with this in place can we provide precise components in the material quality specified by the customer.

Which hurdles did the combined team have to overcome?

Bart Engendahl: The tests that we carried out at Chromatic 3D Materials lasted around a year. Only then did the 3D printing resin exhibit properties that would allow printing to be carried out to the desired level of high quality. During this time, Chromatic 3D also developed new slicing and post-processing software. The format of our cooperation turned out to be optimal: Chromatic 3D is the expert in material formulation and configuration…

Simon Kasböck: …And ViscoTec took responsibility for the dosing technology. Together, we established the perfect printing process for a very complex material and, over the course of our collaboration, we even developed and fully implemented a four-component variant. This went incredibly well, since Chromatic 3D developed the corresponding materials and fully configured these for the process in question. Taking the whole package into consideration, we all see great potential for the Chromatic 3D manufacturing process: The excellent material properties and the stable process make it easy to scale up.

What are the next steps?

Simon Kasböck: We will continue to support Chromatic 3D in optimizing the dosing process and whatever follows on from that. Naturally, we will also remain on board for special tasks in future, such as the development of new variants of our printheads. Additive manufacturing with fluids and pastes is currently not as well known as filament 3D printing or selective laser sintering, for example. Companies such as Chromatic 3D are able to demonstrate the potential of the technology – and that’s extremely important for our business development.