The electronics manufacturing industry keeps changing over time, creating a need for flexibility. Since new and advanced technology is emerging now, the demand for printed circuit boards (PCBs) is increasing as well. To keep up with this demand while also solving the existing problems, PCBWay has announced new integrations of parameters and special processes that are created specifically for flexible PCBs (FPCs).

First, let’s learn what flexible FCBs are. Flexible PCBs, also known as FPCs, are printed circuit boards that can bend, twist, and conform to the shape of the device they’re installed in. For the same reason, they have gained immense popularity in different industries such as wearable gadgets and medical devices.

However, the process of producing FPCs that are durable and high-performing is quite complicated. It requires attention to details and advanced manufacturing techniques. Surprisingly, PCBWay’s latest announcement addresses these challenges by creating new parameters and special processes.

Starting with the new parameters, PCBWay has fine-tuned the old parameters that control the fabrication of FPCs. These parameters control different aspects such as material selection, thickness considerations, and dimensional tolerances. So, the new parameters not only fine-tune these aspects but also meet the quality standards.

Next, the company has also introduced several special processes that enhance the durability, reliability, and overall performance of FPCs. Additionally, the new special processes include advanced surface finishes, impedance control, and specialized lamination techniques which help reduce challenges such as signal integrity issues and mechanical stress.

A person from PCBWay company has emphasized on the commitment of the company for customer satisfaction with a statement, “At PCBWay, we strive to stay ahead of the curve by continuously improving our processes and offerings.” Further he added, “the introduction of new parameters and special processes for FPCs underscores our dedication to providing our customers with the highest quality solutions tailored to their specific needs.”

Since the announcement of these new processes and parameters of the flexible PCBs, many experts in the electronics industry have appreciated these advancements of the PCBWay and their approach towards the evolving demands of flexible PCB manufacturing.

PCBWay’s approach to enhance its capabilities in the domain of flexible PCBs is assured to have a significant impact on numerous sectors, including consumer electronics and automotive. Additionally, PCBWay has paved its position as a trusted partner by producing FPCs that are not only flexible but also reliable and high-performing.

The new approach by PCBWay will improve its positioning and capabilities in the area of FPCs. Hence, the company will also have a significant impact across various sectors, including consumer electronics and automotive. It seems that after the announcement, PCBWay will remain as the leader in the electronics industry.

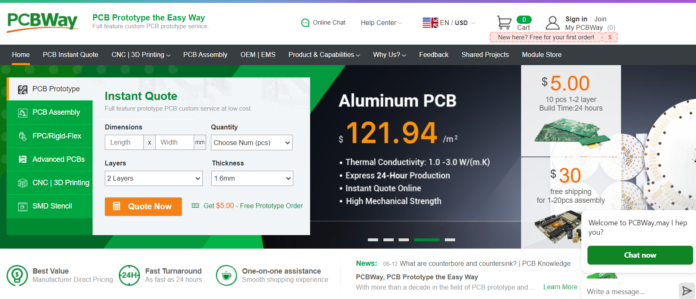

For more information visit their official website of PCBWay and read the new parameters and processes for flexible PCBs in detail.

FAQs on PCBWay’s New Parameters and special process for Flexible PCBs

What Flexible printed circuit (FPCs) board mean? And why are they important?

Flexible PCBs, are special designed printed circuit board that have the ability to bend, or twist and take the space where they are installed. These flexible PCBs are convenient alternative for applications where rigid or non-flexible PCBs doesn’t fit due to shape or space mis-match.

Which new parameter for the Flexible PCBs are introduced of PCBWay?

In order to improve the stringent performance of flexible PCBs, the company PCBWay has introduced a few new parameter at the fabrication level of these flexible PCBs. These new parameters include material selection, thickness consideration of the PCBs and dimensional tolerances.

What are the process for the flexible PCBs that are added at the fabrication level?

At the level of fabrication pf the flexible PCBs, PCBWay has introduced a range of special processes. The process of surface finishing, impedance control, and advance lamination technique are the major one. The objective of these is to ensure durability, performance and reliability of these flexible PCBs

What benefits these new parameters and special processes give in the manufacturing of these flexible PCBs?

PCBWay introduced these new special processes and parameters to address some of the common challenges associated with the manufacturing of the PCBs such as signal integrity issues, and mechanical stress to improve the quality, functionality and reliability of these flexible PCBs.

What are the major industries expected to benefit from the advancement of these Flexible PCBs manufacturing?

Industries with high demand of the flex PCBs such as electronic industry, automotive, medical, wearable-making industry, aerospace industry, etc., are expected to significantly benefit with these advancements in the manufacturing of these flex PCBs.

How PCBWay keeps up the customer satisfaction with these new processes and parameter changes?

PCBWay is committed, and prioritize customer satisfaction to its core purpose to provide industry standard, high quality PCBs with improved performance. These changes in processes and new parameters are implemented keeping the core objective of customer satisfaction unaltered, with advancement in high quality solutions for specific needs of the industries.

Where can I get detailed information of the new parameters and special processes for the flexible PCBs introduced by PCBWay?

Visit here, the official website of PCBWay to get full detailed information on these new processes and parameters of the flexible PCBs.

Is there any possibility for PCBWay to add custom requirements in the flexible PCBs?

Yes. In order to meet specific needs of the industry, PCBWay have this customization option possible for the customers. It can be unique design requirements, specialized material or any custom process, PCBWay believes in working closely with the customers for the customers needs.

How does PCSWay stands-out from the other PCB manufacturers in terms of flex PCB fabrications?

The first thing that makes PCBWay stand out is their commitments to innovation, quality of fabrication, and customer satisfaction. PCBWay is a reliable option with high-quality flexible PCBS unmatched with its competitors with its advanced manufacturing capabilities, years of experienced team and their dedication to continuous improvements.

How can I place an order of flexible PCBs from PCBWay?

The process is simple; visit PCBWay website and submit your design files with its respective quote. Any member from the PCBWay support team will be available to assist your throughput the ordering process and even solve all your queries with respect to product orders and fulfilment.