Although off to a slightly slow start, the market acceptance of EV continues to grow – as does the pace of development. One key factor limiting adoption has been the relative lack of charging points, especially rapid charging points available for ‘in-journey’ charging. In some ways, there is a ‘chicken and egg’ situation as EV sales will be limited until ‘range anxiety’ is overcome with more charging points while companies are reluctant to invest in charging infrastructure until more EV are on the roads.

Currently, to refuel our gasoline vehicles we have only one option, visit one of the thousands of gas stations that are located beside the route on highways and in cities and many towns. With EVs the picture changes; while many gas stations will incorporate charging points, they can be installed almost anywhere a vehicle can be parked – workplaces, public buildings, roadside service areas, residential streets and even in driver’s own residences.

Multiple types of EV exist, with hybrid types (PHEV, Full HEV, MHEV) indicating vehicles that have an alternate source of propulsion, normally an internal combustion engine (ICE). Fully battery-powered vehicles only have electric motors and are denoted BEV while the embryonic fuel cell based vehicles are FCEV. In general hybrid vehicles can self-charge from the ICE, although some types (PHEV) can be charged by plugging them in.

Sales of all types of EV (xEV) are predicted to show accelerating growth over the next few years, with BEV and MHEV showing the strongest growth.

Figure 1: Projected xEV unit sales. Source: IHS, Omdia 2020

To support the growth in xEV, a corresponding growth in charging infrastructure will be required. Currently, the vast majority of charging points are in China – especially for fast chargers where they have over 80% of the installations.

Figure 2: Private and publicly accessible chargers by country, 2019 (IEA2020)

According to research firm, Research and Markets, there will be a 31.8% CAGR in the unit installations between 2020 and 2027 with an associated 39.8% CAGR in value, indicating an increase in pricing during the period.

DC charging standards and protocols

In order for xEV to be charged by publicly available chargers, standardization has to be in place and common protocols have to be agreed. This is particularly important in regions where vehicles often travel from country to country, such as in Europe.

There are three primary protocols in place globally, which draw from a range of international standards. CHAdeMO (charge de move) was started in 2010 in Japan and is supported by the main Japanese companies (Nissan, Mitsubishi, Toyota, Hitachi, Honda and others) as well as several European manufacturers. Drawing upon international standards such as IEC6185 and IEC62196, CHAdeMO defines a specific connector. Also defined are chargers – currently up to 400 kW / 1000V although a partnership with the China Electricity Council is reported to be considering chargers up to 900 kW.

Also Read: How to Manage Long Distance Travel With an Electric Car

Originally started by leading European and American manufacturers including VW, Audi, BMW, Daimler, Ford, GM and Volvo the Combined Charging System (CCS) now includes some Asian manufacturers as well. CCS derives its AC and DC standards from applicable IEC, SAE and ISO standards and is working on charger standards up to 350 kW. There are over 33,000 charging points currently deployed with over half being 50 kW.

The final standard is the fast DC charging Tesla supercharger that is a proprietary standard for Tesla vehicles. There are over 20,000 stations installed that use Tesla’s proprietary connector and deliver power up to 250 kW. In order to extend the network, Tesla are now providing adapters for some vehicles to use CCS charging stations and, in Europe, CCS compatible ports are fitted to some Tesla vehicles.

Charging times with all standards are a function of the battery capacity, its state of charge and the power available from the charging station as well as the maximum charging rate possible for the vehicle. As an example, an ‘average’ vehicle will require 29 minutes to add 266 km of range at 100 kWh charging. This is significantly longer than the 3-5 minutes to refuel a gasoline-powered vehicle and explains why organizations are pushing for ever higher charging rates.

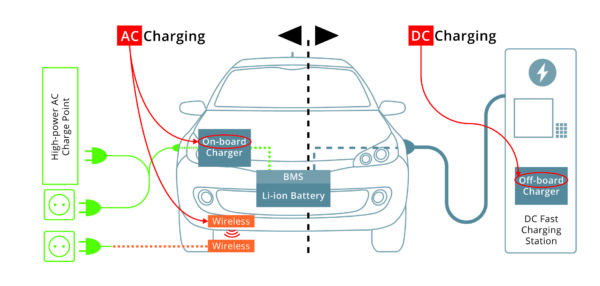

On-board or off-board charging?

There are two types of charging – on-board and off-board. The definition relates to where the conversion to DC is performed. On-board chargers take AC from the wall outlet or charging point into the vehicle where an on-board charger converts this to DC for charging the battery. Conversely, off-board chargers convert to DC internally and then provide DC to the vehicle which charges the battery directly.

Figure 3: Charging can be either on-board or off-board (Yole Development)

Fast DC Charging and associated power topologies

Fast DC chargers contain two stages in the main powertrain – a power factor correction (PFC) stage and a DC/DC conversion stage. There are several PFC boost topologies that are available and suited to unidirectional charging including NPC, T-NPC and 6-switch.

Figure 4: Typical Three−Phase Power Factor Correction (PFC) Boost Topologies for Fast DC EV−Charging. T−NPC (top−left), 6−switch (top−right) and I−NPC (bottom)

As consideration is being given to using the energy stored in the vehicle battery to power homes during times of expensive electricity, the ability to operate bidirectionally is becoming increasingly important. All of the topologies shown would support this mode of operation, albeit with some of the diodes replaced with switches.

Silicon carbide (SiC) MOSFETs with low internal resistance RDSon (in the sub-40mΩ region) are the preferred solution, especially for higher power ranges due to their higher efficiency than their silicon counterparts. Ideally, these would be embodied in power integrated modules (PIMs) as these integrated solutions offer better performance and simplify design as well as reducing system size and enhancing reliability. The T-Neutral Point Clamp (T-NPC) type also requires 1200 V diodes (or switches for bi-directional operation), while the NPC uses switches such as 650 V SiC MOSFETs or IGBTs.

For the DC/DC conversion stage there are two primary topologies used; the full-bridge resonant LLC and full-bridge with Zero Voltage Switching (ZVS). The LLC enables Zero Voltage Switching (ZVS) on the primary and often allows Zero Current Switching (ZCS) on the secondary, which results in very high efficiency levels when operating close to the resonant frequency. Provided the operating frequency is limited, LLC converters can be a highly efficient solution, although parallel operation is challenging due to the difficulties associated with current sharing and synchronization.

Phase-shifted full-bridge topologies are also common and these benefit from a less complex control architecture than LLC approaches. With ZVS, efficiency is high across a wide range of output voltages which is ideal to support both 400 V and 800 V battery voltages.

While there are notable differences, both the LLC and phase-shifted full-bridge have similar component counts and achieve similar power densities. Both approaches are suited to synchronous secondary rectification which makes them both suited to bidirectional operation.

onsemi offers a wide range of products suited to high efficiency EV charging applications including SiC diodes and MOSFETs, SiC power modules and associated gate drivers.

SiC Schottky diodes provide superior switching and enhanced reliability over silicon due, in part, to their excellent thermal performance. Available in 650 V, 1200 V and 1700 V versions, onsemi SiC diodes have no reverse recovery current and temperature independent switching characteristics.

SiC MOSFETs are both fast and rugged with a 10x higher dielectric breakdown field strength, 2x higher electron saturation velocity, 3x higher energy band gap and 3x higher thermal conductivity. They are available in 650 V, 900 V and 1200 V versions.

System benefits of SiC diodes and MOSFETs include delivering the highest possible efficiency by reducing power loss as well as greater power density, higher operating frequency, increased temperature operation and reduced EMI.

SiC boost power modules contain SiC diodes and SiC MOSFETs and are used in DC/DC converter stages. The fully integrated approach reduces parasitic elements and enhances thermal performance as well as simplifying design and reducing board space.

Alongside these solutions, onsemi also offers isolated gate drivers for WBG switches that enhance system efficiency and reliability.

Summary

Providing a wide charging network of fast chargers is considered to be one of the critical success factors for growing sales of EV over the next few years. Several standards exist, each coming from different industry groups and, while there are notable differences, there is commonality in the need for greater power and enhanced efficiency.

SiC devices hold the key to delivering the fast charging that will make EVs successful and commonplace and onsemi is a leader in this technology area with a comprehensive range of SiC diodes, MOSFETs, power modules and associated gate drivers.