Ventec International Group is well-known for the production of high-quality, high-performance PCB laminates also called copper-clad laminates and prepregs used in a wide range of Printed Circuit boards (PCB) and associated applications. Copper-clad laminate (CCL) is the PCB substrate used in PCB manufacturing. It supports interconnection and insulation for the printed circuit board and also impacts the transmission speed, energy loss and characteristic impedance of the signal in the circuit. Our technical editor, Pratibha Rawat had a F2F interview with KIM SAUER and ANDY JABBAR from Ventec International Group at Productronica held in Greater Noida India. They share how Ventec products are supporting the Indian Markets in various verticals like smartphones, 5G and automotive and how they channel the supply chain for uninterrupted services.

Kindly introduce Ventec International Group to our readers.

KIM SAUER, GLOBAL MARKETING DIRECTOR: Ventec International is a global PCB laminate manufacturer. A listed company in Taiwan, we have manufacturing facilities in Taiwan, USA and China and sales, technical support and warehousing facilities in key markets all around the world, including Europe and America.

We specialize in advanced niche markets, particularly in the areas of automotive, consumer electronics, aeronautics, and RF materials.

We are very excited to be at Productronica here in India for the first time; although we already have a long history with Indian customers through both direct relationships and via our dedicated Indian distribution partner, it’s an important and exciting growing market for us with many opportunities.

5G, Mobile Phones and Automotive are the hottest topics. What does Ventec have to offer to Indian customers related to these segments?

ANDY JABBAR, Business Development, CBC: Smartphones use high-density interconnect (HDI) technology due to the miniaturization of the electronic devices used in their manufacture. Only AT&S in India currently use this technology for mass production and Ventec produce the laminates they use in their HDI manufacturing.

For the automotive sector in India, we’re already doing a lot of work. Ventec supplies its insulated metal substrate (IMS) materials to customers here in the automotive space, and we also have products designed specifically for the production of automobile headlamps and the cluster.

Our range includes 5G-ready PCB material solutions as well. Our tec-speed 20.0 range is a high-speed/low-loss PCB material portfolio that combines unrivalled high-frequency performance with Dk of 3.00 to 3.48, and Df 0.002 to 0.0037; superior loss characteristics; and the extremely high reliability that’s particularly demanded by 5G applications.

Ventec has 7 years of presence in India. What changes have you seen so far after the new PLI scheme introduction? What are the markets Ventec caters to?

ANDY: We are already seeing technology upgradation happening in PCB manufacturing. I think people are benefiting from PLI and other schemes the government has introduced. The Indian market is moving towards technology upgradation and so customers are moving from low-end laminates to products that are a little higher-end and Ventec has a wide range of solutions for those high-end needs.

Our materials are used for signal integrity-related products and also in RF where they find application in radars and antennas. We have a significant interest in the defence and aerospace market, with our products certified by NASA. In India, we already have a defence segment customer that uses our boards.

Thermal management is a key issue, what does Ventec have for it?

ANDY: This is a broad segment where lot of research and development is taking place. Ventec has 14 and 17 kilowatt products that are currently in an experimental phase before we deploy them to India and the rest of the world. Most of the European automobile manufacturers – Mercedes, Volkswagen and BMW, for example – use our thermal management products extensively.

KIM: We’re seeing an increase in demand for thermal management solutions globally. The automotive market and aerospace are important sectors where our laminates are key. We offer a range of products that perform with exceptional reliability to solve thermal issues in very tough environments.

Which are Ventec’s target industries?

KIM: The automotive and aerospace manufacturers are our key customers, and a lot of them are global players. Excitingly, when looking at India, there are a lot of manufacturers of domestic automotive brands that we are keen to target as well.

ANDY: For example, in the automotive sector, Mahindra is already using our IMS material and heat products.

What effect Ventec has experienced in terms of the supply chain?

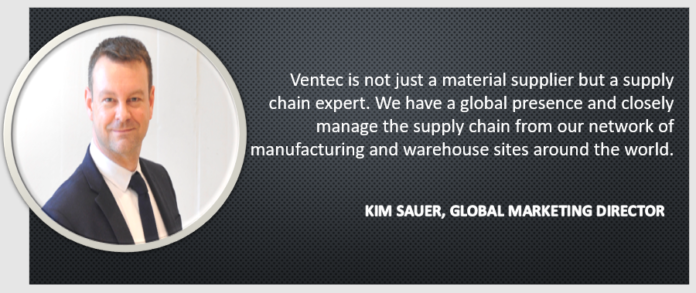

KIM: Ventec is not just a material supplier but a supply chain expert. We have a global presence and closely manage the supply chain from our network of manufacturing and warehouse sites around the world. We put a lot of emphasis on managing the supply chain for our customers.

Unplanned events that occur around the world affect everybody, but we continue to successfully face those challenges to ensure a continuous supply. It is not just about supply chain issues; we work closely with our customers to find the best material for their needs and ensure their products go to the market on time.

ANDY: A key strength is that we have manufacturing and warehousing facilities in Taiwan, China, Europe and USA . From these multiple global locations, we can swiftly cater for our customers no matter where in the world. We’re pleased to continue to bring that strong level of reliable supply chain to our customers in India.