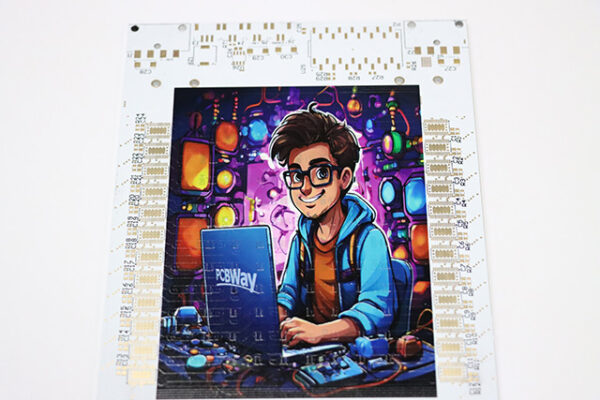

The innovations in printing technologies have always complemented the PCB manufacturing industry by offering freedom of flexibility and creativity while designing the PCB board. Earlier the constraint of using single-colour marking and text was the only option for silkscreen printing on solder masks which had left no choice for new possibilities. However, the latest innovations in printing technology have revolutionized the process of printing by offering color PCB printing directly onto the PCB surface by allowing options for colourful pictures and patterns.

As always PCBWAY is standing parallel to this innovation by adding UV printing equipment to its manufacturing portfolio which allows customers to opt for colourful images and intricate patterns, marking onto PCB, thus eradicating the need to go with monochromatic markings. The newly added UV printing technology utilizes UV-curable inks to accomplish high-definition image printing on various materials including fibreglass boards, metal substrates, ceramic substrates, flexible boards, and rigid-flex boards.

Let us explore how COLOR PCB Printing will help to boost your PCB manufacturing landscape

1. Components Identification: Using different colours for components like resistors, capacitors integrated circuits etc. helps the assembler to identify and place components quickly while assembling them and avoid the cumbersome task of identifying them by carefully watching.

2. Color-coded marking and identifiers: The multicolour silkscreen printing allows key areas, holes, test points, connectors and other elements for clear labelling onto the PCB surface. It can also be used to increase the board friendliness to the user by indicating the pins, polarity and signal paths.

3. Improved Branding: Multi-colour printing allows the customer to add any custom design which can be a logo, graphics, or product name to the board for more visually appealing PCBs or they can simply place their brand name which will also reflect its authenticity.

4. Customization and Personalization: From consumer electronics to the industrial sector, from automotive to the gaming industry the colourful print images open up new creative possibilities and improve the aesthetic of the board. It brings unprecedented flexibility, creativity, and customization options.

How to Use PCBWay’s Color PCB Printing Service?

PCBWAY caters to all your needs for multicolour silkscreen printing with just a few steps to ensure accurate smooth printing.

1. The customers should note the maximum size for a single piece of PCB is 270 x 470mm.

2. Select the desired background solder mask colour as part of the specification.

Before submitting the image, specify the purpose of the image and the desired printing position. The image which should be positioned must be of high quality and clarity for accurate reading and reference during the printing process.

3. Before the process, customers should communicate the above details to the PCBWAY team and accompanying instructions or precautions to ensure correct printing with timely deliveries.

For instance, if the customer wants to provide Gerber data, the following pre-requisite are needed:

1. These specifications involve drill holes, traces, solder masks, and outline designs, all of which must meet the designated requirements outlined by the manufacturer

2. For designing coloured characters reference pictures and reference alignment maps are enough, although for Gerber design the desired coloured characters should not be placed over surface mount pads or through hole pads to avoid interference with components placement and soldering process. They should be placed exclusively on a silkscreen layer and marked with appropriate colours for clarity.

3. Several file types are supported for the overall effect files of coloured boards, including PDF, JPEG, PNG, and TIFF.

4.. However, a positioning diagram or reference diagram is needed to guarantee precise alignment and interpretation of the coloured pieces. The manufacturer uses this diagram as a reference to ensure that the necessary coloured pieces are precisely placed and executed on the PCB. Customers can minimise any errors or discrepancies in the manufacturing process and ensure the successful realization of their PCB designs by following these design criteria and providing the required reference materials.

Just go and bring your creativity to life with UV printing technology services offered by PCBWAY.