PolySwitch Devices for Li-Battery Protection:

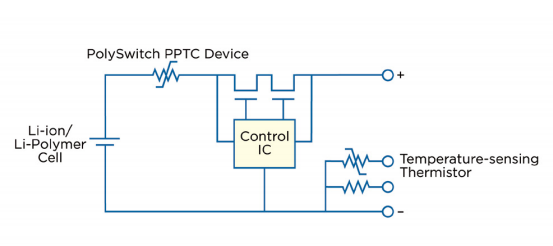

Li-packs typically include ICs capable of detecting and implementing an overvoltage lockout, undervoltage lockout, overtemperature protection and overcurrent protection. ICs and MOSFETs are often used as the primary pack protection in conjunction with a fuel gauge device to track the battery cell capacity, state-of-charge (%), run-time to empty (minutes), battery voltage (mV) and temperature.

A PolySwitch PPTC device placed in series with the battery helps provide a second level of protection in the event of a control circuit malfunctioning (Figure 1). Although the semiconductor circuitry is considered reliable, there are conditions under which failure of the primary protection may occur, including excessive electrostatic discharge, high temperature or oscillation during a short circuit condition. In these cases, the PolySwitch PPTC device helps provide cell overtemperature protection on charge and discharge, as well as redundant overcurrent protection. When a PolySwitch PPTC device is included in the circuit, the temperature of the device increases accordingly as the cell temperature rises and less current is required to trip the device.

A wide selection of PolySwitch PPTC products is offered for Li-battery protection. The PolySwitch family includes devices offering a range of thermal cutoff (activation temperatures) from 85°C to 125°C. The PolySwitch PPTC device’s low resistance helps meet the battery pack’s resistance budget requirements, and its low trip temperature helps provide protection against thermal runaway in case of an abusive overcharge. PolySwitch PPTC resettable devices are also available in a variety of form factors and current ratings.

PolySwitch Strap Products: Installation Method – Spot Weld:

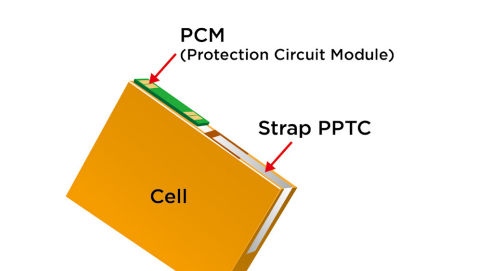

PolySwitch strap products offered by Littelfuse include the SRP, LR4, VTP, VLR, VLP, MGP and MXP families. Strap devices, which come in a flat, tab-like form factor, can be incorporated into cylindrical based packs, prismatic cells or even pouch packs and can be applied to specific battery chemistries or usage profiles. Their installation method is to be spot welded to cells or straps in the battery pack (Figure 2).

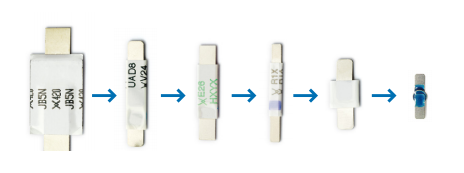

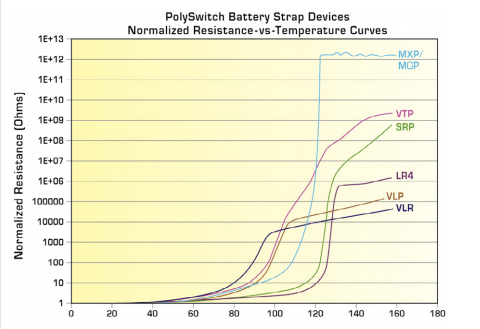

The evolution of Littelfuse’s strap devices has progressed to lower resistance, smaller form factors and increased thermal protection, as shown in Figures 3 and 4.

ambient temperatures.