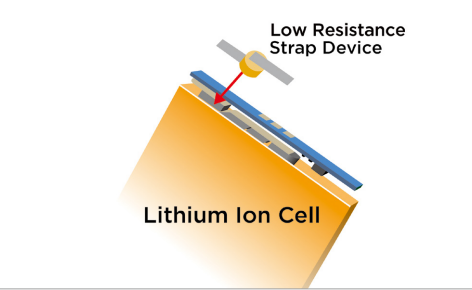

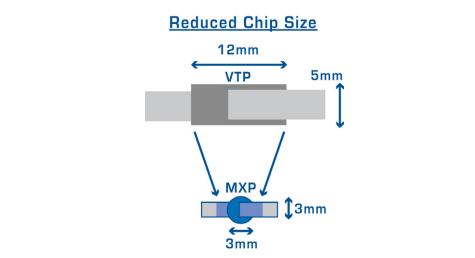

The PolySwitch low-resistance (low rho) MXP strap device, shown in Figure 5, incorporates conductive metal particles to achieve lower resistance than traditional carbon blackfilled PPTC devices. The MXP device is 88% smaller than the prior-generation VTP strap device (Figure 6), while also providing approximately the same hold current at 60°C. Regardless of the pack chemistry, device hold current is selected on the basis of the maximum average charge or discharge current and takes into account the maximum operating temperature. The form factor will depend on the available space within the pack. PolySwitch PPTC strap devices with activation temperatures (thermal cutoff) from 85°C to 125°C are offered in a wide range of custom and standard configurations.

placed under the PCB. (The MXP Strap length and configuration can also be customized per customer requirements.)

device has lower resistance in a smaller form factor.

PolySwitch L-Tab Devices: Installation Methods – Reflow Solder and Spot Weld:

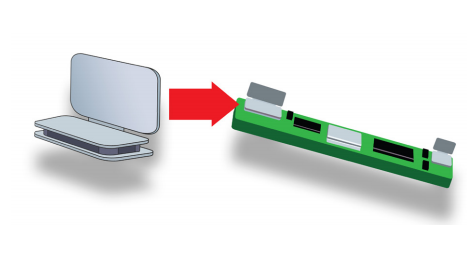

The PolySwitch L-Tab device helps provide a weldable and reflowable devices. The L-Tab device can be reflow soldered onto the battery PCM at one end and the device’s L-shaped tab/terminal can be directly welded to the battery cell tab at the other end, therefore providing cost savings. Additionally, its “L” shape assists in reducing manufacturing steps when the PCM is folded into the pack. With operating current up to of 4A at room temperature, they are suitable for use for battery protection in highperformance tablets. They also offer ultra-low resistance to help maintain the system impedance budget. Locating protection circuitry in close proximity to the cell helps eliminate the need for long metal interconnects and helps improve thermal sensing (Figure 7).

terminal block.

PolySwitch Surface-Mount Products: Installation Method – Reflow Soldering:

Littelfuse surface-mount products are well suited for battery PCMs since their smaller size helps save board space and eases design complexity. Our standard 1206 (nano) and 1210 (micro) form factor offer low profiles and small form factors that can be reflow soldered. The lower resistance of these devices help maintain the system impedance budget.