PolySwitch Disc Products: Installation Method – Press Fit

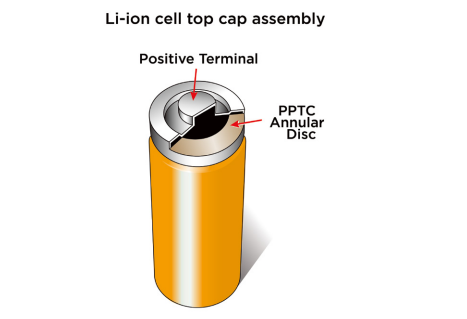

A PolySwitch disc device is a bare disc made of PPTC material that is placed inside a Lithium-ion 18650 cylindrical cell header to help protect cells during shipping and handling prior to assembly in packs (Figure 8).

The disc device also helps provide protection for cells that are sold individually as AA and AAA-sized, non-rechargeable lithium batteries for consumer use. Each disc device is custom designed for the cell it will be used with.

MHP-TA Devices: Installation method – Spot Weld

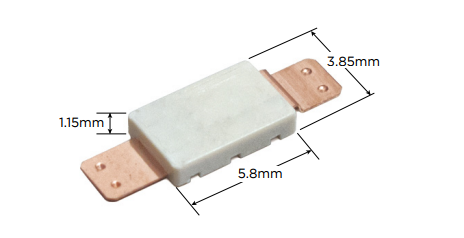

The MHP-TA devices offer a space-saving solution for protecting higher energy Lithium-polymer and prismatic battery pack applications such as ultra-thin notebooks and tablets. These resettable thermal cut-off (TCO) devices consist of a PolySwitch PPTC device in parallel with a bimetallic protector. They activate thermally at temperatures from 72°C to 90°C, while also offering a high withstand voltage and high hold currents from 6A to 20A at room temperature.

ultra-thin notebooks.

Available in an ultra-low-profile (L: 5.8mm x W: 3.85mm x H: 1.15mm) package (Figure 9), Their benefits include their extremely low resistance, ability to open by thermal activation and their resettability. The MHP-TA device eliminates the non-latching properties of traditional bimetals because the built-in PPTC keeps the bimetal contacts latched open during a fault condition.

Selecting Circuit Protection Devices

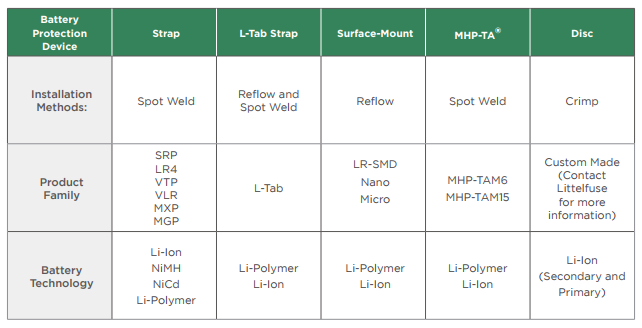

Table 1 shows a selection of Littelfuse PolySwitch devices that are suitable for Li-battery protection: PolySwitch PPTC devices (strap, surface-mount, disc, L-Tab), as well as the MHP-TA devices.

When adding protection devices, battery pack designers must decide what level of protection is required for each application. A system test should be used to determine whether or not a specific protection device is appropriate.

The protection requirement is cell chemistry-dependent and precise protection requirements should be obtained from the cell manufacturer. Recommendations from device manufacturers are useful in narrowing protection options and benchmarking other pack protection schemes may help provide a good lead for further investigation. However, specific testing of each protection option is the best way to evaluate its effectiveness.

Summary

Battery applications designers must respond to the trend toward more space-efficient battery packs that require eversmaller protection devices. Littelfuse PolySwitch offers them many different protection devices to choose from in an array of form factors and device characteristics that meet the needs of their particular design.